Get a quoate

Why Indian Clients Trust Boben Panels for Modular Cleanrooms?

Published : 2026-01-06In the pharmaceutical and precision electronics industries, cleanroom walls are more than mere barriers—they serve as the final line of defense against contamination. Recently, a delegation from a renowned pharmaceutical engineering general contractor in Mumbai, India, traveled 4,000 kilometers specifically to visit the Boben factory. Their objective was clear: to source the highest-quality “skeleton” and “skin”—cleanroom color-coated steel panels—for multiple upcoming modular cleanroom projects.

- Captivated by Appearance, Enchanted by Precision: The Awe of On-Site Testing India’s pharmaceutical industry is globally renowned for its rigorous adherence to GMP standards, leading clients to demand near-perfect sheet quality. Within Boben’s fully automated production facility, machines hum in organized harmony. Rather than relying solely on presentations, the client immediately picked up calipers and straight edges. “Flatness deviation must be controlled within 0.5mm.” This was the client’s non-negotiable requirement. When they randomly selected a freshly produced 50mm hand-finished rock wool panel and pressed the straightedge flush against its surface, light couldn’t penetrate the gap. Mr. Singh nodded repeatedly: “Boben’s panel flatness even surpasses some samples we’ve seen in Europe. This mirror-like flatness is crucial for minimizing dust accumulation in cleanroom dead zones.”

- Peeling Back the Core to Reveal Quality: The Confidence of Genuine Materials Modular cleanrooms require frequent disassembly and relocation, placing stringent demands on the strength of color-coated steel panels and the adhesion of core materials. To validate quality, we conducted an on-site destructive test. Technicians cut open a glass-magnesium rock wool panel to demonstrate its internal structure to clients:

1.Panel: Constructed with 0.5mm high-tensile color-coated steel from renowned brands, offering exceptional corrosion resistance and withstanding VHP (hydrogen peroxide vapor) sterilization.

2.Frame: Perimeter reinforced with thickened galvanized steel edging, ensuring seamless modular assembly and high load-bearing capacity.

3. Core Material: High-density hydrophobic rock wool achieves Class A fire rating. Through Boben’s proprietary fully automated adhesive coating process, it bonds seamlessly with the panel surface, eliminating hollow spots and delamination.

Seeing such solid construction, the normally stern client finally broke into a smile: “This is exactly what we wanted—industrial-grade panels that will stand the test of time.”

III. Modular Adaptability: Accelerating Installation The primary focus of this customer’s procurement was for modular cleanrooms. Boben’s technical team demonstrated the convenience of center-mounted aluminum connections and tongue-and-groove joints on-site. Our color-coated steel panels undergo precision prefabrication according to drawings before shipment, with pre-cut openings for switches/sockets and return air vents. The client recognized that using Boben’s prefabricated panels would reduce their on-site construction cycle in India by at least 30%, which is crucial for seizing market opportunities.

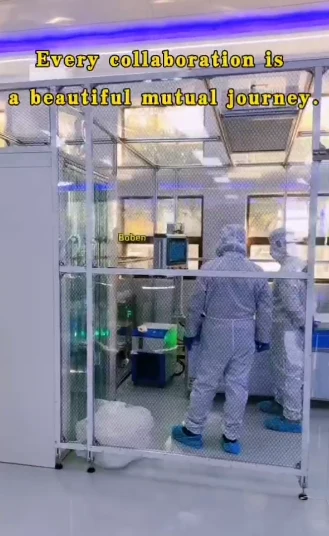

Accompanied by BOBEN’s professional team, the Indian clients first entered the intelligent production workshop. Inside, multiple automated production lines operated in an orderly manner, achieving meticulous control throughout the entire process—from raw material cutting and core material lamination to finished product inspection. “Our modular cleanroom color steel panels are composed of high-quality base sheets laminated with high-performance core materials. Core products include various types such as rock wool, glass-magnesium, and aluminum honeycomb, all customizable to meet different cleanliness grade requirements,” explained BOBEN’s Technical Director to the clients. “ explained BOBEN’s Technical Director to the clients. ”For the Indian market, all exported color steel panels have obtained BIS certification and strictly comply with Indian IS standards. Each batch comes with comprehensive inspection reports and certification documents to ensure smooth customs clearance and market entry.” The clients carefully observed the production process, pausing frequently to inquire about key technical details. They expressed high recognition for the workshop’s automation level and standardized management.

The visit by our Indian clients represents more than a simple procurement trip—it stands as the highest accolade for Boben’s “Made in China with Intelligence” quality. At Boben, we don’t produce ordinary building materials; we craft precision shields for pristine environments.