Get a quoate

What is the ISO standard for clean rooms?

Published : 2025-11-27In global manufacturing, scientific research, healthcare, and other fields, cleanrooms require a unified standard for evaluating cleanliness—this is the core value of ISO standards. It is not a complex technical barrier, but rather a “language of cleanliness” that global enterprises and regulatory bodies can understand, clearly defining cleanroom classification levels, testing methods, and performance requirements. For enterprises, ISO-compliant cleanrooms not only guarantee product quality but also serve as a “passport” to international markets. As a specialized manufacturer deeply rooted in the cleanroom industry, boben Modular Cleanroom Manufacturers has long integrated ISO standards into every aspect of product design, positioning itself as a reliable partner for companies seeking compliance and global market expansion.

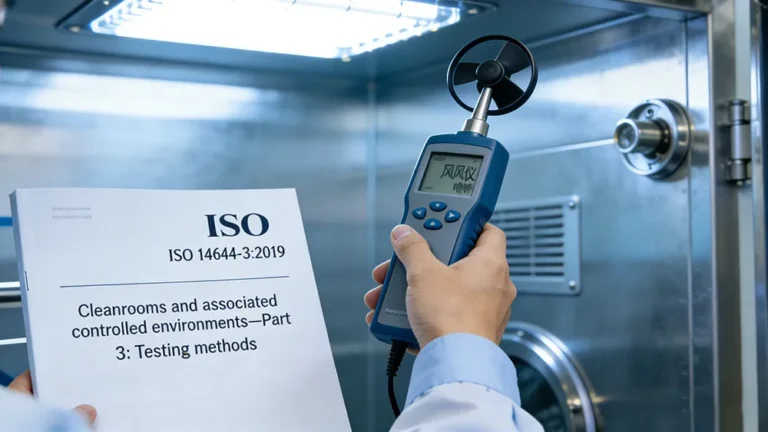

The core ISO standards for cleanrooms originate from the ISO 14644 series, which serves as the globally recognized classification and testing guidelines for cleanrooms. The standard classifies cleanrooms from ISO Class 1 to ISO Class 9, with lower numbers indicating higher cleanliness levels: ISO Class 1 represents the highest cleanliness standard, allowing no more than 10 particles larger than 0.5 microns per cubic meter of air. It is commonly used in chip manufacturing and high-end semiconductor industries. ISO Class 5 (corresponding to the traditional “Class 100”) permits no more than 35,200 particles per cubic meter, making it the standard for biopharmaceuticals and sterile drug production. ISO Class 8 (equivalent to the traditional “Class 100,000”) is suitable for food processing and general electronics assembly, permitting up to 3.52 million particles per cubic meter. This clear classification enables companies to precisely select the appropriate cleanliness level based on their industry requirements, avoiding cost inefficiencies from “over-compliance.”

Beyond particle control, ISO standards also specify critical parameters for cleanrooms, including temperature, humidity, pressure differentials, airflow velocity, and settled microbial counts. For instance, the pharmaceutical industry must not only meet ISO Class 5 particle standards but also comply with the ISO 14698 series of biological contamination control standards to ensure zero microbial contamination within cleanrooms. The electronics industry must control electrostatic parameters to prevent dust adhesion and component damage. These standards not only regulate cleanroom construction and operation but also provide a unified basis for quality alignment across different countries and enterprises—a pharmaceutical company certified to ISO Class 5 can gain trust from regulatory bodies and customers worldwide.

For enterprises, adhering to ISO standards in cleanroom construction may appear as a “mandatory requirement,” but it actually represents an “invisible advantage.” Firstly, compliance is the foundation for market access. Whether it’s China’s GMP, the U.S. FDA, or the EU’s CE certification, ISO standards serve as the core basis for audits. Companies failing to meet these standards cannot enter high-end markets. Secondly, standardized norms significantly enhance product qualification rates and reduce production losses caused by environmental fluctuations. Finally, ISO certification serves as an endorsement of corporate capability, bolstering client confidence and facilitating international business expansion. boben Modular Cleanroom Manufacturers precisely addresses these core business needs. Their modular cleanroom products are designed from the outset to align with the ISO 14644 series standards, with material selection, system configuration, and testing procedures strictly adhering to the guidelines. This ensures swift third-party certification post-delivery, saving enterprises valuable time and effort.

The advantage of boben Modular Cleanroom Manufacturers lies not only in helping enterprises meet ISO standards but also in providing “customized + cost-effective” solutions. Addressing industry-specific ISO requirements—such as anti-static needs in electronics or bio-contamination control in pharmaceuticals—boben tailors airflow organization, filtration systems, and monitoring protocols. Its modular production model reduces construction time by over 50%, while factory-prefabricated standardized modules ensure precise error control and stable cleanroom performance. Additionally, boben offers ISO standard testing guidance and compliance documentation support, delivering end-to-end services from design to final inspection and certification. This allows enterprises to focus on core operations without worrying about technical details.

In today’s intensifying global competition, ISO-compliant cleanrooms are no longer a “nice-to-have” but an “essential requirement” for corporate survival and growth. Selecting a compliant, stable, and industry-tailored cleanroom solution paves the way for long-term business development. Leveraging years of ISO implementation experience, mature modular technology, and comprehensive after-sales service, boben Modular Cleanroom Manufacturers has helped numerous global enterprises achieve cleanroom compliance and successfully expand into international markets.

If you’re grappling with achieving ISO cleanroom standards, concerned about technical complexity or stringent audits, consider boben Modular Cleanroom Manufacturers’ customized solutions. Our expert team will recommend suitable ISO grades and technical approaches based on your industry characteristics and target market regulations, ensuring your cleanroom construction is both compliant and hassle-free. Choosing boben means aligning with international standards, turning your cleanroom into a “passport” for global market expansion and driving steady business growth.