Get a quoate

What is Cleanroom Construction? Definition, ISO Grades & Core Standards Explained

Published : 2025-12-11In the construction and engineering sector, a Cleanroom is far more than just a “clean room.” It is a specialized, enclosed environment where environmental parameters—such as airborne particulates, temperature, humidity, air pressure, and microbial levels—are strictly controlled.

It is a complex engineering system integrating architectural structure, ventilation, filtration technology, and intelligent control. Its core objective is to create a stable environment that prevents contaminants from compromising product quality or scientific research.

With 14 years of deep expertise, boben Modular Cleanroom Manufacturers specializes in flexible, high-efficiency solutions, making us the preferred partner for architectural cleanroom projects worldwide.

1.Core Design Principles of a Cleanroom

The heart of cleanroom design is “Contamination Control.” This is achieved through three critical systems:

A. Air Purification System

This is the “heart” of the cleanroom. It uses a three-stage filtration system (Pre-filter + Medium filter + HEPA/ULPA filter) to capture dust and microorganisms.

- boben Modular Cleanroom Suppliers utilize H13-H14 grade HEPA filters with an efficiency of 99.99% or higher, ensuring the air quality meets ISO Classes 1 through 9 tailored to your needs.

B. Airflow Organization

Depending on the application, we employ Vertical Laminar Flow, Horizontal Laminar Flow, or Turbulent Flow.

- The Goal: Uniform air supply and rapid return air speeds eliminate “dead zones” (vortices), ensuring contaminants are flushed out immediately rather than accumulating.

C. Differential Pressure & Sealing

- Pressure Control: Cleanrooms maintain a specific pressure difference (positive or negative) relative to adjacent areas to prevent unfiltered air from infiltrating.

- Sealing: We use high-performance materials, such as hermetic doors, seamless flooring, and dust-free ceiling systems, to eliminate any potential leakage paths.

- Environmental Control: Integrated systems precisely manage temperature (±1℃), humidity (±5% RH), static electricity, and noise (≤60dB).

2.Cleanrooms in Construction: Key Characteristics & Benefits

Precise ISO Classification

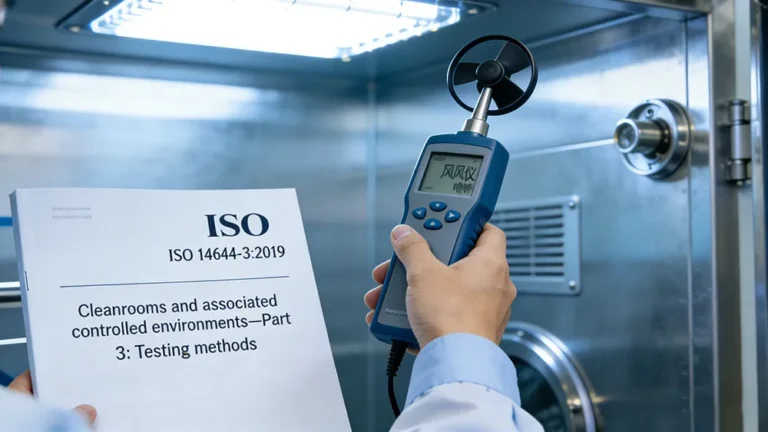

Cleanrooms are graded by cleanliness according to ISO 14644 standards, ranging from ISO Class 1 (cleanest) to ISO Class 9.

- Chip Manufacturing: Requires ISO 1-3.

- Pharmaceuticals: Typically ISO 5-7.

- Food Processing: Generally ISO 8-9.

Modular Design: Flexible & Efficient

Traditional cleanroom construction involves long lead times and difficult renovations. In contrast, boben Modular Cleanroom Manufacturers champion the Modular Cleanroom approach.

- Speed: Uses prefabricated components for on-site assembly, reducing construction time by over 50%.

- Flexibility: Can be easily disassembled, relocated, or expanded as your production capacity grows, significantly lowering renovation costs.

Energy Efficiency & Sustainability

By optimizing fan selection, using low-resistance filters, and integrating heat recovery systems, our modular cleanrooms reduce energy consumption by 20%-30% compared to traditional builds. We use low-VOC, easy-to-clean materials aligned with global green building trends.

Stability & Maintenance

Standardized components make maintenance and part replacement effortless. Paired with intelligent monitoring systems, users can track cleanliness, pressure, and humidity in real-time, with automatic alarms for any abnormalities.

3.Typical Application Scenarios

Cleanrooms are now essential infrastructure across various industries:

- Electronics & Semiconductors: Chip manufacturing and circuit assembly require ISO 1-5 environments to prevent dust from causing short circuits or defects.

- Bio-Pharmaceuticals: Vaccine R&D and sterile preparations require ISO 5-7 environments that strictly adhere to GMP and FDA standards to prevent microbial contamination.

- Food & Beverage: Aseptic filling and supplement production require ISO 8-9 standards to ensure food safety and hygiene.

- Scientific Research: Microbiology labs, gene sequencing, and nanotechnology centers rely on stable environments for experimental accuracy.

- Other Fields: Aerospace precision parts, medical device manufacturing, and cosmetics.

4.Why Switch to Modular Cleanrooms?

In modern construction, modular cleanrooms are replacing traditional builds because they are:

boben Modular Cleanroom Suppliers have successfully delivered thousands of projects in dozens of countries across electronics, pharmaceuticals, and research sectors. Our clients trust us for our flexibility, stability, and professional service.

Whether you are planning a new facility or retrofitting an existing building, choosing boben Modular Cleanroom Suppliers ensures a high-efficiency, custom-tailored solution.

Ready to build your controlled environment? Contact us today for a specialized proposal and quote!