Get a quoate

Ultrasonic instrument industry ISO8 cleanroom

Published : 2025-12-05Project Overview: Clean Upgrade of Precision Manufacturing

| Customer Industry | Ultrasonic Instrument Manufacturing |

| Application requirements | Precision assembly, debugging, and packaging of ultrasonic transducers and core circuit boards |

| Cleanliness level | ISO 8 (Class 100000) |

| Key configurations | modular clean room, efficient FFU system, integrated air shower device |

| Project Challenge | Need to deploy quickly within existing R&D/production areas without affecting surrounding work. |

Our solution: modular clean room with rapid deployment and dual protection

We have provided an integrated and efficient modular clean room solution for the ultrasound instrument customer, perfectly addressing their dual requirements for speed and cleanliness.

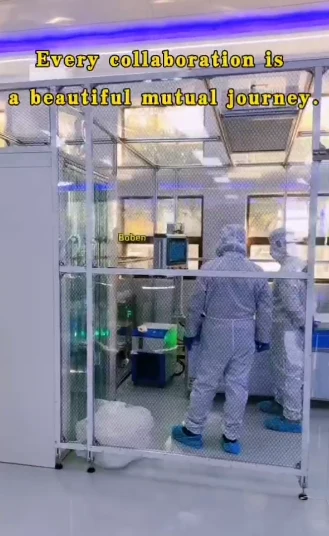

1. High strength aluminum alloy frame: adopting professional modular design to achieve rapid on-site splicing and installation (as shown in the picture), greatly reducing the construction period and minimizing the impact on the customer’s existing production environment.

2.Efficient FFU filtration system: Multiple high-efficiency FFUs (fan filtration units) are integrated at the top, using HEPA filters to ensure that the air exchange rate (ACH) inside the clean room meets the standard and maintains a stable ISO8 cleanliness level.

3.Integrated Air Shower: Customize a small integrated air shower room at the inlet and outlet, and use high-speed clean air to effectively remove dust attached to the surface of work clothes before operators enter, thus controlling the pollution brought in by personnel from the source.

Whether you are in the medical device, ultrasound electronics, semiconductor, or new energy battery industries, we can provide fast, customized, and highly compliant modular clean solutions. Click to contact us, upload your venue photos and cleanliness requirements, and immediately get a quick quote and 3D solution design for your ISO grade cleanroom!