Get a quoate

What are the different types of cleanrooms?

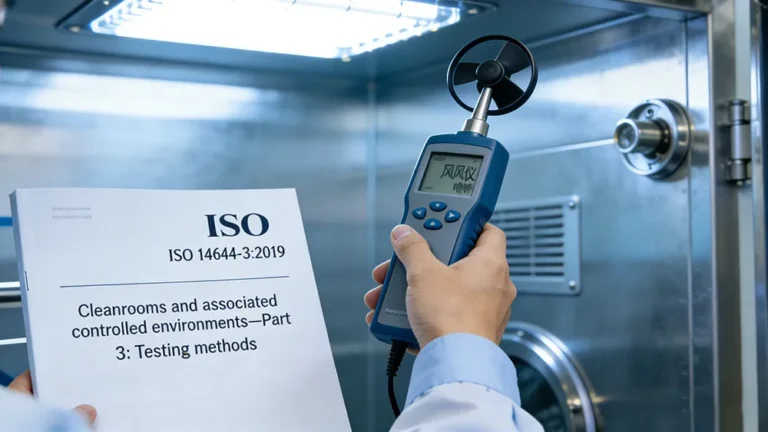

Published : 2025-11-27In industries with stringent environmental requirements—such as electronics manufacturing, biopharmaceuticals, and scientific research—cleanrooms are not one-size-fits-all standardized products. Instead, they branch into multiple types based on industry needs, cleanliness levels, and application scenarios. Selecting the right cleanroom type is akin to finding a “custom-fit space” for production or research, ensuring compliance while avoiding unnecessary costs. Below, we break down the five most common cleanroom types to help you quickly identify the right fit. Boben Modular Cleanroom Manufacturers has already developed customized solutions for each category, becoming the trusted choice for numerous enterprises.

The first category is precision-grade cleanrooms classified by cleanliness levels, covering mainstream requirements from Class 100 to Class 100,000. Class 100 cleanrooms represent the pinnacle of precision, with no more than 3,500 particles larger than 0.5 microns per cubic meter of air. They are primarily used in scenarios with zero tolerance for dust, such as chip manufacturing and high-end medical device assembly. Class 1,000 and Class 10,000 cleanrooms suit electronic component and LCD panel production, while Class 100,000 is commonly chosen for food processing and standard pharmaceutical packaging. boben Modular Cleanroom Manufacturers can integrate corresponding HEPA filtration systems and airflow control technologies to precisely meet each cleanliness grade requirement.

The second category classifies cleanrooms by airflow patterns, primarily into three types: vertical laminar flow, horizontal laminar flow, and turbulent flow. Vertical laminar flow cleanrooms generate uniform airflow through ceiling-based supply and floor-based return, rapidly removing contaminants. They are suitable for semiconductors and biosafety laboratories. Horizontal laminar flow rooms deliver air horizontally and are commonly used for precision instrument testing. Turbulent flow cleanrooms rely on air turbulence mixing for filtration, offering lower costs and suitability for general electronics assembly, food baking, and similar applications. boben Modular Cleanroom Manufacturers’ modular products allow flexible switching between airflow patterns. Duct designs are optimized during factory prefabrication based on requirements, eliminating the need for additional adjustments after on-site assembly.

The third category comprises “purpose-driven” cleanrooms tailored directly to industry-specific requirements. Industrial cleanrooms focus on dust control for sectors like electronics and automotive component manufacturing. Biological cleanrooms emphasize sterile containment for applications such as vaccine development and sterile drug production, requiring both dust control and microbial suppression. Laboratory cleanrooms prioritize environmental stability for scientific activities including chemical testing and biological sample cultivation. These cleanrooms demand high customization. Leveraging extensive industry experience, boben modular cleanroom manufacturers precisely match specialized parameters for diverse applications—from temperature and humidity control to differential pressure regulation—all tailored to specific requirements.

The fourth type is the “mobile flexible” modular cleanroom, representing the current mainstream trend. Unlike traditional fixed cleanrooms, modular cleanrooms are assembled from prefabricated modules, enabling rapid installation, disassembly, relocation, and scalable expansion. This flexibility saves time and costs for startups setting up temporary production lines or established companies expanding operations across locations. This type perfectly aligns with modern enterprises’ flexible production needs. Boben Modular Cleanroom Manufacturers stands out as a leader in modular solutions, offering products that balance stability and flexibility, eliminating concerns over site changes or capacity adjustments.

The fifth type is the “special environment” cleanroom, designed for extreme requirements. Examples include:

Anti-static cleanrooms, which utilize specialized flooring and wall materials to prevent electrostatic damage to electronic components; Constant temperature and humidity cleanrooms maintain fluctuations within ±1°C and ±5%, suitable for precision chemical and optical instrument manufacturing; Negative pressure cleanrooms prevent contaminant leakage through pressure differential control, commonly used in biosafety laboratories and infectious disease research facilities.

When selecting a cleanroom, matching the appropriate type is fundamental, while manufacturer reliability is critical. boben Modular Cleanroom Manufacturers, with years of industry expertise, not only covers all the above cleanroom types for customization but also provides one-stop services from solution design and module production to on-site installation. Whether you require a Class 100 high-precision cleanroom or flexible, mobile modular products, you’ll find tailored solutions here. Contact us immediately to have our professional team customize a solution for you, making your cleanroom a true “asset” for your business growth.