Products

Featured products

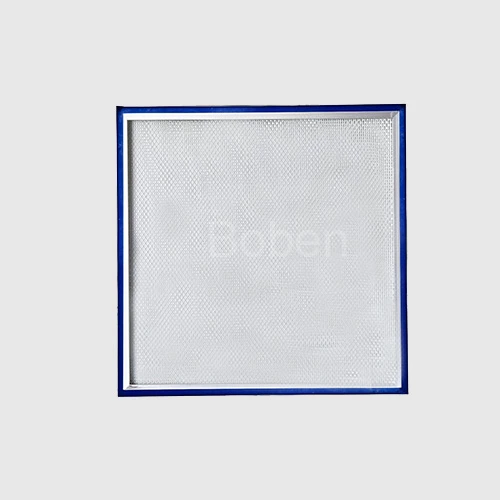

Weighing Chamber

The Boben Weighing Chamber is a specialized clean weighing device for powder and granular materials. Featuring ISO Class 5 cleanliness and negative pressure design to eliminate dust dispersion and cross-contamination, it incorporates H13 HEPA filtration and a 304 stainless steel body for easy cleaning. Compatible with global voltages and diverse applications, it delivers compliant, reliable, and user-friendly operation.

Features:

- Negative pressure + HEPA filtration for dust prevention and cross-contamination control

- ISO Class 5 cleanliness ensures dust-free weighing

- 304/316L stainless steel housing for easy cleaning and corrosion resistance

- Intelligent monitoring + clogging alarm with operational visualization

- Modular design for convenient maintenance and replacement

What is a weighing chamber?

A weighing chamber, also commonly referred to within the industry as a “sampling cart” or “laminar flow hood,” is a specialized purification device that provides a localized Class 100 (ISO 5) clean environment.

Primarily used in pharmaceutical manufacturing, microbiological analysis, and scientific laboratories, it controls dust and reagent handling during weighing and dispensing. Through specific airflow organization, it confines airborne particles within a defined zone for filtration, preventing dust from escaping into the surrounding environment or being inhaled by personnel.

Simply put: It acts as a protective shield. Safeguarding personnel, protecting products, and preserving the production environment.

Why Choose Our Weighing Rooms?

Amidst the multitude of options in the market, it’s often the details that determine the quality of equipment. At boben Modular Cleanroom Manufacturers, our modular design philosophy focuses on three key aspects:

A. Modular & Easy-to-Clean Design

This addresses a real pain point: many older weighing rooms have “dead corners” where powder accumulates and becomes extremely difficult to clean.

- Seamless Welding: We utilize SUS304 stainless steel in a single-piece construction with rounded interior corners (R-radius). A simple wipe with a cloth leaves surfaces spotless, eliminating bacterial breeding grounds.

- Modular Assembly: Facilitates on-site installation and future relocation.

B. Intelligent Control System

Say goodbye to complex control panels. We offer touchscreen controls with real-time display of pressure differential, air velocity, and temperature/humidity.

- Automatic Frequency Conversion: The system automatically detects filter clogging and adjusts fan speed to maintain consistent airflow.

- Alarm Function: The system triggers automatic alerts for abnormal air velocity or when filter replacement is required.

C. Ultimate Safety

- Equipped with DOP detection ports and PAO injection ports for convenient third-party validation.

- Unique liquid-trough sealing technology ensures zero leakage from high-efficiency filters.

Technical Specifications Comparison Table

| Parameters | Standard | High-End |

| Cleanliness | Class 100 (ISO 5) @ ≥0.5μm | Class 100 (ISO 5) @ ≥0.5μm |

| Air Velocity | 0.36 ~ 0.54 m/s (adjustable) | 0.45 m/s ± 20% (automatically maintained) |

| Noise | ≤ 75 dB(A) | ≤ 70 dB(A) (Silent Design) |

| Material | Interior: SUS304,Exterior: Powder-coated steel plate | All SUS304 / 316L stainless steel |

| Filter | Primary G4 + Medium F8 + High Efficiency H13 | Primary G4 + Medium F8 + Wet-Type H14 |

| Control | Button-type panel | Siemens/PLC touchscreen |

Applications: Beyond Pharmaceuticals

While international brands like boben Modular Cleanroom Manufacturers are primarily renowned in high-end pharmaceuticals, high-quality weighing chambers are actually widely used across multiple industries:

- Pharmaceutical Industry: Active Pharmaceutical Ingredient (API) weighing, antibiotic filling, sampling.

- Fine Chemicals: Processing of dyes, pigments, cosmetic powders.

- Laboratory Research: Animal testing, microbial culture preparation.

- Food Industry: Precise formulation of nutritional fortifiers and additives.

In today’s fiercely competitive global market, whether you seek ultimate cost-performance or high-end customization on par with boben Modular Cleanroom Suppliers, we have the capability to provide you with the most suitable cleanroom solutions.

Our equipment undergoes rigorous Factory Acceptance Testing (FAT) and operates reliably in multiple countries worldwide.

Ready to upgrade your production environment?

Contact our technical team directly. We don’t just sell—we are your cleanroom engineering consultants.

Act Now:Customize Your Rapid Clean Space!

Don’t let lengthy lead times slow down your production schedule.Contact our cleanroom experts for a free design consultation and customized quote to kickstart your fast-track production journey.