Products

Featured products

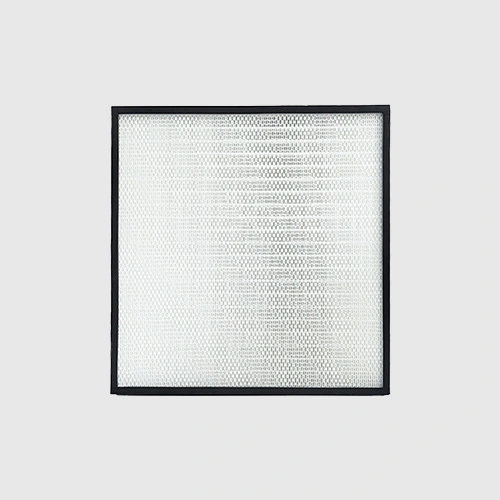

HEPA Filter (Non-woven)

As the core component for cleanroom air purification, the HEPA filter stands out with its key advantages of “high-efficiency filtration, compact energy efficiency, and stable durability,” making it an essential configuration for electronics, pharmaceuticals, scientific research, and other applications. Their core strengths stem from precision manufacturing and premium materials: utilizing H13-H14 grade ultra-fine glass fiber filter media, they achieve filtration efficiencies exceeding 99.99%. These filters effectively capture particles and microorganisms as small as 0.3μm, ensuring cleanrooms effortlessly meet ISO Class 1-5 high-cleanliness standards.

Features:

- Filter paper resists aging, extending lifespan by 30% and reducing replacement costs and downtime.

- Standardized interfaces ensure compatibility with multiple devices, eliminating retrofitting for direct adaptation.

- Environmentally friendly with zero VOC emissions, RoHS compliant, suitable for food and pharmaceutical applications.

- Operating noise ≤55dB ensures quiet operation without disrupting work.

- Independent testing + unique serial number enables data traceability, simplifying certification and re-inspection.

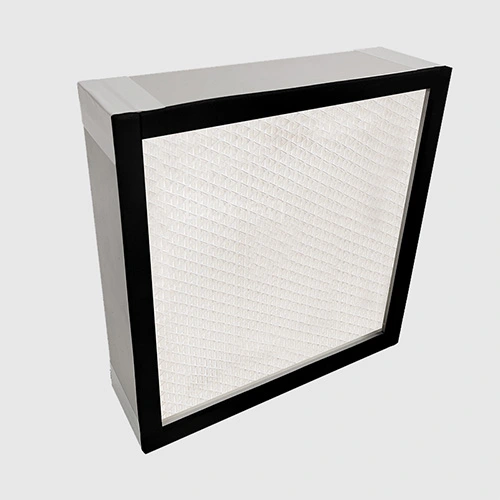

Why choose non-woven design?

High-efficiency filters (non-pleated), commonly known in the industry as Mini-Pleat Filters, serve as the core terminal filtration elements in modern cleanrooms, FFUs (Fan Filter Units), and laminar flow hood systems. Utilizing a unique hot-melt adhesive separation technology instead of traditional aluminum foil or cardboard separators, they achieve high dust-holding capacity, low operating resistance, and a slim, lightweight design.

1.Maximum Dust Holding Capacity with Lower Resistance

Traditional filters use aluminum foil or cardboard as separators to maintain pleat spacing, which occupies valuable filtration area within the filter.

- boben’s solution: We replace conventional separators with specialized hot-melt beads. These beads are finer, more uniform, and occupy minimal space, enabling higher pleat density (Mini-Pleat).

- Your Benefits: Within the same dimensions, our pleatless filters deliver greater effective filtration area. This directly translates to over 30% increased dust-holding capacity and significantly reduced initial resistance. Lower resistance means your fans consume less energy (saving electricity) and operate longer.

2.Lighter, Thinner, Easier to Install

In space-constrained environments such as hospital operating rooms, biosafety laboratories, or microelectronics production lines, the lightweight and slim profile of pleatless filters is particularly crucial.

- The non-pleated structure significantly reduces the overall thickness of the filter, resulting in lower weight.

- This makes it an ideal choice for ceiling-mounted air supply modules (FFUs), reducing ceiling loads and enabling faster, safer installation and maintenance.

3.Superior Sealing and Uniform Airflow Distribution

The non-partitioned design ensures highly consistent spacing between pleat layers.

- This eliminates localized airflow irregularities or “short-circuiting” that may occur with traditional partitions.

- The result: More uniform air velocity distribution across the filter surface, enabling full filtration efficiency throughout the entire filter area and delivering more reliable cleanliness performance.

Application Areas:

As a renowned boben Modular Cleanroom Manufacturer, our frameless HEPA filters are standard equipment for the following industries:

When you choose boben, you’re not just buying a filter—you’re gaining a complete cleanliness solution. Click below to leave a message and connect with boben’s cleanroom experts to learn how our HEPA filters deliver significant value for your business.

Act Now:Customize Your Rapid Clean Space!

Don’t let lengthy lead times slow down your production schedule.Contact our cleanroom experts for a free design consultation and customized quote to kickstart your fast-track production journey.