Products

Featured products

Fan Filter Units

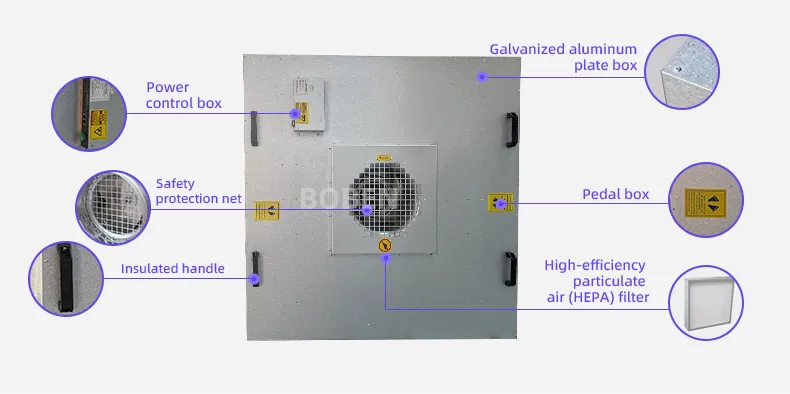

Premium Industrial FFU: ISO 5-8 Certified, H13/H14 HEPA (99.99% Efficiency). Durable Galvalume housing with OHS-compliant safety guards and insulated handles for secure, easy maintenance. Features 3-speed control for energy-saving, low-noise (<52dB) airflow. Factory direct supply to UAE, Australia & Turkey with bulk discounts and custom sizes. Get your expert cleanroom quote today!

Features:

- Equipped with German Schloer or EBM fans, offering advantages such as extended lifespan, high static pressure, low energy consumption, and minimal noise.

- FFU filter media utilizes American HV or LYDALL filter paper.

- The FFU outer casing is constructed from stainless steel plate. Alternatives include aerospace aluminum plate, galvanized aluminum-zinc plate, or electrostatic-sprayed cold-rolled steel plate, offering lightweight properties, corrosion resistance, rust prevention, and an aesthetically pleasing appearance.

- Prior to shipment, each unit undergoes particle counter scanning in accordance with Federal Standard 209E to ensure quality compliance.

Are you looking for a reliable cleanroom partner? We provide industrial-grade Fan Filter Units (FFU) engineered for high performance and low energy consumption.

Specifications for Our FFU Products

We at Boben support custom non-standard specifications and provide complimentary design solutions. Add us on WhatsApp at +8613862527051

Many buyers focus solely on price during procurement, overlooking hidden operational costs: excessive noise causing employee fatigue, uneven airflow leading to product dust accumulation, and high energy consumption eroding factory profits. We understand your concerns. As a core component of boben Modular Cleanroom Manufacturers’ purification systems, our FFU is engineered to address these pain points—it’s not just a fan plus filter, it’s the guardian of your production line’s yield.

Product Information

| Product Information | |||

|---|---|---|---|

| Support for non-standard customization | |||

| External Dimensions (mm) | 575*575*320 | 1175*575*320 | 1175*1175*320 |

| Filter Dimensions (mm) | 570*570*70 | 1170*570*70 | 1170*1170*70 |

| Rated Air Volume | 500 | 1000 | 2000 |

| Cleanliness Level | Class 100 | ||

| Power Supply | 220V, 50Hz | ||

| Noise Level | ≤ 60dB | ||

| Casing Material | Galvalume Steel or Stainless Steel Sheet | ||

| Motor Type | AC or DC Motor | ||

| Control Mode | Single Unit Control, On-site, or Remote Computer Group Control | ||

Why do global customers choose our FFU?

1.Industrial-Grade FFU with Safety Guard

Built-in high-strength metal safety guard, durable and corrosion-resistant, effectively prevents accidental contact with high-speed rotating blades during maintenance or operation. This design fully complies with stringent Occupational Health and Safety (OHS) standards in markets such as Australia, minimizing workplace injury risks. Provides stable, reliable, and ISO-compliant clean working environments for pharmaceutical workshops, semiconductor factories, and various biological laboratories. The housing utilizes premium stainless steel or galvanized aluminum-zinc sheet material, featuring a smooth, easy-to-clean surface that prevents dust accumulation and ensures compliance with sterile room cleanliness requirements.

2.Environmentally friendly galvanized aluminum sheet material

All-weather corrosion resistance, utilizing high-performance eco-friendly galvanized aluminum panels with exceptional rust and corrosion protection. Maintains long-term rust-free operation even in high-humidity regions like Bangladesh. The robust yet lightweight structure reduces load pressure on cleanroom ceilings, while its sturdy design ensures low vibration and noise levels during high-speed operation. Compliant with global green production standards, it is an ideal choice for LEED-certified or ISO cleanroom projects.

3.Three-Speed Intelligent Speed Control System

Flexible airflow control with a user-friendly three-speed adjustment knob (High, Medium, Low) allows real-time airflow adjustment to meet varying cleanliness requirements (ISO 5-8). Paired with a high-efficiency motor, low-speed operation significantly reduces electricity costs, making it ideal for the highly energy-efficient Australian market. Eliminating complex programming, the simple and reliable mechanical knob design greatly simplifies operation for on-site personnel.

4.Insulated Safety Handle

Standard high-insulation handle crafted from engineering-grade, high-impedance insulating material. Specifically engineered for demanding industrial electrical environments, it physically eliminates potential static electricity or leakage hazards. Enhances on-site efficiency with a robust handle design that strategically positions load-bearing points during handling, making heavy equipment lifting and relocation more effortless and stable.Considering that installation personnel may wear professional protective gloves, the handle spacing is scientifically calculated to ensure easy grip even in confined cleanroom ceiling spaces, significantly reducing installation time.

5.Industrial-Grade HEPA High-Efficiency Filter

Featuring a high-airflow, low-resistance design, this professional-grade H13/H14 HEPA filter achieves over 99.99% filtration efficiency for particles as small as 0.3μm. Its unique pleated filter media process increases effective filtration area, delivering powerful airflow while significantly reducing airflow resistance and extending motor lifespan. By optimizing the internal micro-pore structure, the filter ensures clean air is delivered downward in a uniform vertical laminar flow, eliminating dead zones in airflow. This effortlessly assists laboratories or production workshops in meeting the stringent requirements of ISO 5 (Class 100) certification, serving as the core safeguard for pharmaceutical sterile rooms and semiconductor cleanrooms.

As a key component of boben Modular Cleanroom Manufacturers’ integrated solutions, this FFU has been exported alongside our modular cleanrooms to Southeast Asia, the Middle East, and European markets, enduring long-term testing under varying voltages and climatic conditions.Request a Design Quote WhatsApp:+8613862527051

Our Case Studies

Our Commitment:

- Core Motor Warranty: Extended warranty coverage provided.

- Rugged Packaging: Export-grade fumigation-free wooden crates with shock-absorbing foam lining ensure undamaged delivery across oceans.

- Global Voltage Adaptability: Customizable for 110V/60Hz, 220V/50Hz, or even 380V three-phase power.

Typical Application Scenarios:

- Electronic Semiconductors: Lithography equipment areas, wafer dicing workshops (requiring static elimination).

- Biopharmaceuticals: Vaccine filling lines, sterile laboratories (requiring resistance to disinfectant corrosion).

- Food Processing: Sterile packaging workshops.

- Clean Booths and Laminar Flow Hoods: For rapid setup of localized high-cleanliness zones.

If your facility is facing issues like excessive energy consumption, subpar cleanliness, or aging equipment, it’s time for an upgrade. Don’t let substandard fan units hold back your production efficiency.

Choosing our FFUs means selecting an internationally validated aerodynamic system. Whether you require replacement for a single unit or need boben Modular Cleanroom Manufacturers to design and build a complete modular cleanroom solution, we stand ready to serve you.

Contact us immediately to receive airflow curve diagrams, detailed specification sheets, and our most competitive quotation. Together, let us safeguard your precision manufacturing operations.

Act Now:Customize Your Rapid Clean Space!

Don’t let lengthy lead times slow down your production schedule.Contact our cleanroom experts for a free design consultation and customized quote to kickstart your fast-track production journey.