Products

Featured products

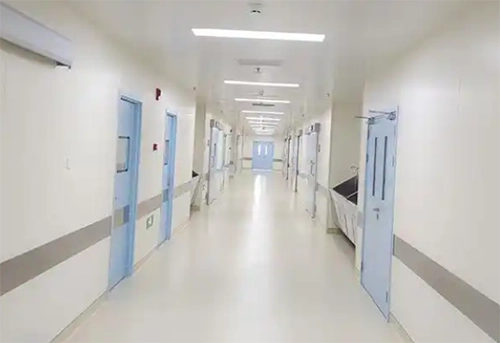

Clean room:From Design to Certification

We provide global B-level solutions that comply with ISO 1-8 standards. Our cleanroom design enables rapid assembly (7-15 days) without the need for major renovations, saving customers time and costs.Our cleanroom is equipped with high-efficiency air filters (99.995% filtration), precise temperature/humidity control, and adjustable pressure to ensure zero cross contamination. They are made of 304 stainless steel, durable, energy-saving, easy to maintain, and comply with GMP, FDA, and CE standards.From pharmaceuticals to electronics, from food to laboratories, we provide customized layouts and 24/7 technical support. Contact us immediately for a free quote and turnkey solution!

Features:

Why Choose Our Cleanroom?

Designed for global industries, our cleanrooms meet ISO 14644-1 & GMP standards, delivering reliable sterility and cost efficiency.

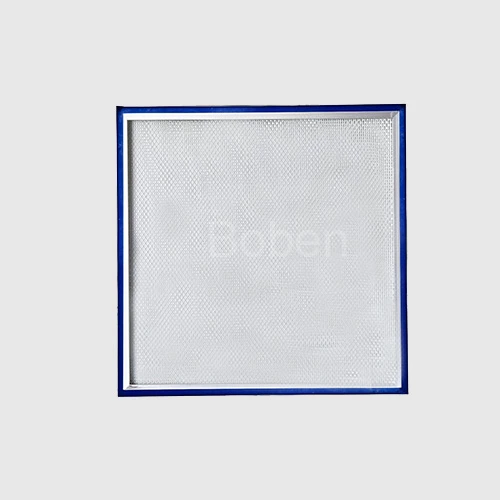

1.Guaranteed ISO Compliance & Precision Filtration

“Stop worrying about audits. Our cleanrooms are pre-verified to meet ISO Class 5 to Class 8 standards. We utilize H14 Gel Seal HEPA Units (99.995% efficiency) to ensure absolute sterility for Pharmaceutical and Electronic manufacturing.”

2.Comprehensive Integrated Ecosystem

“We don’t just build walls; we engineer the entire workflow. Our system seamlessly integrates Dynamic Pass Boxes with electronic interlocks and Air Showers to prevent cross-contamination, creating a cohesive, airtight barrier for your critical processes.”

3.Rapid Deployment & Modular Flexibility

“Time is money. Our modular design allows for 60% faster installation compared to traditional construction. Whether you need to expand, reconfigure, or relocate, our standardized panels and connection systems adapt to your business growth.”

4.Industrial-Grade Durability

“Built to last in harsh environments. We use premium SUS304 Stainless Steel for critical components like Pass Boxes and Air Showers, offering superior corrosion resistance and easy sterilization compared to standard coated steel alternatives.”

Ready to build your ISO-compliant facility? Get a free 3D design layout today.WhatsApp: Instant Support: +86 138 6252 7051

Core Specifications

|

Parameter |

Details |

|---|---|

|

Cleanliness Class |

ISO 1 (Class 10) – ISO 8 (Class 100,000) |

|

Filtration Efficiency |

HEPA H14 (99.995% @ 0.3μm) / ULPA U15 Optional |

|

Temp Control |

18-26℃ (±0.5℃) |

|

Humidity Control |

30-70% RH (±5%) |

|

Installation Time |

7-15 Days (Modular Fast Assembly) |

|

Applicable Industries |

Pharma, Electronics, Food, Lab, Medical Device |

Key Advantages

Case Showcase

Contact us for free customized quotes and technical drawings! Our team provides free after-sales support and on-site video installation guidance.

Boben Modular Cleanroom Manufacturers provides one-stop services from solution design, module production, overseas transportation, on-site installation, and after-sales maintenance. Our professional team is available 24/7 online, with spare parts warehouses in key areas. No matter which country you are in, you can receive timely technical support and maintenance services. For 14 years, we have provided customized solutions to hundreds of B2B customers worldwide, from electronic factories to pharmaceutical workshops, from research laboratories to food processing plants. Each clean room operates stably and has become a trusted “quality support” for our customers.

Choosing a clean room essentially means choosing “stable quality assurance” and “worry free collaborative experience”. Boben Modular Cleanroom Manufacturers, with 14 years of technological accumulation, global compliance experience, and one-stop service, allows you to no longer worry about the construction, acceptance, and maintenance of cleanrooms. Contact us now and provide us with your cleanliness level, space size, and industry requirements to get free customized solutions and accurate quotes, making cleanrooms a true “bonus point” for enterprise development and helping you establish a foothold in the global market!

The core of a cleanroom is not “looking clean”, but “data that meets standards and is stable”. It requires precise control of key parameters such as particles, microorganisms, temperature and humidity, and pressure difference in the air through an efficient HEPA filtration system, fully sealed enclosure structure, and directional airflow design. From ISO Level 1 (top-level cleanliness, suitable for chip manufacturing) to ISO Level 9 (100000 level, suitable for food processing), the requirements for cleanliness levels vary greatly across different industries and processes. For example, the vaccine production workshop requires an ISO level 5 sterile environment, and electronic component assembly needs to control static electricity. These cannot rely on “approximate compliance” and must comply with international standards throughout the entire process.

And Boben’s first advantage is’ making compliance easy ‘. As a senior foreign trade manufacturer, our products strictly follow global standards such as ISO 14644, FDA, GMP, CE, etc. From material selection to production testing, every link is executed in accordance with international norms. When delivered, complete technical documents, testing reports, and acceptance materials will be provided. Whether you are targeting Southeast Asia, the Middle East, or the European market, you can easily pass the review of local regulatory agencies without having to repeatedly modify and adjust for compliance, saving a lot of time and cost.

The second core advantage is “quick implementation without delaying production”. Traditional clean rooms require civil construction and on-site welding, often taking two to three months to complete, causing many companies to miss the market window period. Boben adopts a “factory prefabrication+on-site assembly” model, where all core modules are produced in a standardized manner in the factory. After being transported to the site, they are assembled like “building blocks” and can be installed and debugged in 1-2 weeks, shortening the traditional construction period by more than 80%. For enterprises engaged in emergency production expansion and the establishment of new factories, this high efficiency directly translates into market competitiveness.

Act Now:Customize Your Rapid Clean Space!

Don’t let lengthy lead times slow down your production schedule.Contact our cleanroom experts for a free design consultation and customized quote to kickstart your fast-track production journey.