Products

Featured products

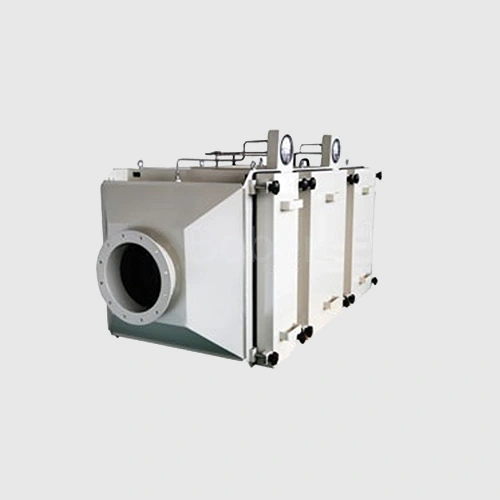

Bag-in/Bag-out Filter

The BIBO system is a modular housing specifically designed to isolate contaminated filters. Its core value lies in enabling HEPA/ULPA filter replacement without direct operator contact with any contaminated media.Each BIBO module undergoes rigorous airtightness testing prior to shipment to ensure the enclosure’s integrity.

Features:

- Supports customization in size/function/ISO 5-8 grades for multi-industry applications; factory-direct pricing with 40% lower energy consumption

- English manual + multilingual support; global direct shipping with rapid after-sales parts availability

- Split packaging saves 30% on shipping costs; no professional installation required—quick assembly reduces labor expenses.

- Wide voltage range (110-240V), moisture-resistant, and withstands extreme temperatures for harsh climates.

- Fully certified with ISO/CE/SGS, compliant with global industry standards across multiple regions.

In pharmaceuticals, biotechnology, nuclear, and chemical industries, handling Highly Potent Active Pharmaceutical Ingredients (HPAPI), cytotoxic drugs, or biohazards poses a critical challenge: ensuring filtration efficiency while preventing operator and environmental contamination during filter changes.

The boben Bag-In/Bag-Out (BIBO) system is a critical safety infrastructure designed to address this challenge. It enables contact-free filter replacement, making it an essential configuration for high-risk operational environments worldwide.

Core Product Value:

| Value Dimensions | Description | Customer Benefit |

| Ultimate Safety | The entire filter replacement process occurs within a sealed, dedicated bag, ensuring zero contact between operators and contaminants. | Eliminates personnel exposure risks, meeting the most stringent OHS standards. |

| International Compliance | Complies with GMP requirements, providing complete IQ/OQ validation documentation and DOP/PAO test ports. | Successfully passes international audits by FDA, EMA, and others, accelerating compliance processes. |

| Flexible Modularity | Supports customizable multi-stage filtration configurations (e.g., pre-filter + HEPA + HEPA) to accommodate varying toxicity levels. | Highly scalable system easily integrates into existing HVAC systems. |

| Stable Operation | Features highly reliable sealing clamping mechanisms and corrosion-resistant stainless steel housing. | Ensures long-term stable and reliable operation, reducing maintenance frequency and operational costs. |

Why Choose boben BIBO?

Our BIBO system design focuses on details to ensure flawless performance even in the most demanding environments.

1.Structure and Material Integrity

- Material Standards: Standard 304 stainless steel housing, upgradeable to 316L stainless steel. Finely polished surfaces ensure corrosion resistance and ease of bio-decontamination.

- Airtightness Assurance: All welds meet stringent standards, guaranteeing zero leakage under operational pressure differentials.

2.Unique Filter Change Mechanism

- Dedicated Sealed Bag System: A specially designed long bag is fitted over the filter frame. During replacement, the old filter is pushed into the bag, where the operator seals and cuts it externally, creating a complete physical barrier isolation.

- High-Pressure Clamping Device: An automatic/manual screw-type clamping mechanism applies uniform and reliable pressure to the filter gasket, ensuring no bypass leakage between the installed HEPA filter and the frame.

3.Optional Integration Features

- VHP Sterilization Interface: Integrated VHP (Vaporized Hydrogen Peroxide) nozzles enable online biodecontamination of the filter enclosure interior prior to replacement, achieving 6-log spore kill levels.

- DOP/PAO Scan Port: Dedicated testing and scanning port reserved for on-site filter integrity testing (FIT) by customers or third-party agencies.

- Differential Pressure Monitoring: Capable of integrating a high-precision digital differential pressure gauge for real-time monitoring of filter loading status, providing accurate replacement timing alert.

Application Scenarios:

Our BIBO system has been successfully deployed at leading pharmaceutical and research institutions worldwide. Contact us for customized quotation proposals.

| Industry | Specific Application | Solution |

| Pharmaceutical/HPAPI | Exhaust ventilation for sterile isolators, exhaust ventilation for high-toxicity powder weighing rooms | Safely handle OEB 4/5 compounds to prevent environmental contamination. |

| Biolaboratories | BSL-3 / BSL-4 Laboratory Exhaust Systems | Ensure pathogens are securely captured, achieving absolute containment. |

| Nuclear Industry | Capture of radioactive dust and aerosols | Provides a robust 316L stainless steel structure meeting long-term stability requirements. |

As a professional cleanroom manufacturer, boben Modular Cleanroom Manufacturers delivers more than just BIBO modules—we provide integrated solutions with high safety levels. Our engineers are well-versed in international HVAC standards, ensuring your system meets the highest requirements from design and manufacturing through to on-site integration.

Three Steps to Your Custom BIBO Solution:

- Submit Requirements: Inform us of your target airflow (CMH or CFM) and application toxicity level.

- Receive 3D Design: Our engineers will provide detailed system configuration diagrams and 3D renderings.

- Get Final Quote: Obtain a transparent, professional international trade quotation.

Click here to contact boben Modular Cleanroom Manufacturers’ international sales team and let us help you build a zero-risk working environment.

Act Now:Customize Your Rapid Clean Space!

Don’t let lengthy lead times slow down your production schedule.Contact our cleanroom experts for a free design consultation and customized quote to kickstart your fast-track production journey.