Get a quoate

Modular Cleanroom Manufacturers in Vietnam | Custom ISO Solutions

Published : 2025-12-18With the global manufacturing shift toward Southeast Asia, Vietnam has emerged as a premier hub for high-end industries, including electronics, medical devices, and food processing. This growth is driven by competitive labor costs and proactive government policies. As these sectors evolve, the demand for cleanrooms—the critical infrastructure required to ensure product quality and regulatory compliance—has surged.

boben Modular Cleanroom Manufacturers, a professional leader in the field, provides customized cleanroom solutions specifically engineered to meet the unique environmental and industrial demands of the Vietnamese market.

1.The Role of Cleanrooms in Vietnam’s Industrial Expansion

In Vietnam’s booming industrial ecosystem, cleanrooms (often referred to as “dust-free rooms”) have transitioned from a luxury to a “standard requirement” for high-end manufacturing. Their role is defined by three key factors:

- Ensuring Product Stability and Yield: Industries such as semiconductors and precision machinery operate at the micron level. Even trace amounts of dust or microbial contamination can lead to significant product failure. Cleanrooms control airborne particles, temperature, and humidity to minimize contamination risks at the source.

- Facilitating Global Export Compliance: Vietnamese manufacturing is heavily export-oriented. To enter markets like the EU and the US, local companies must meet rigorous standards such as GMP or ISO 14644. A certified cleanroom is a prerequisite for passing these international audits.

- Supporting Industrial Upgrading: As Vietnam shifts from labor-intensive to technology-intensive production, traditional factory environments are no longer sufficient. The adoption of advanced cleanrooms is a hallmark of this industrial maturation.

2. Advantages of Prefabricated Modular Cleanrooms

Compared to traditional “stick-built” (permanent) construction, prefabricated modular cleanrooms are better suited to the fast-paced Vietnamese market. boben Cleanroom suppliers focuses on four core value dimensions:

Rapid Deployment: Traditional construction can take 3 to 6 months. In contrast, modular cleanrooms utilize a “factory-prefabricated + on-site assembly” model. A standard 200㎡ cleanroom can typically be completed within 15 to 30 days, allowing companies to respond rapidly to new orders.

1、Flexibility and Portability: Many manufacturers in Vietnam operate in leased facilities. Unlike permanent structures, modular cleanrooms do not require destructive floor drilling and can be dismantled, moved, or expanded. This results in a fixed-asset reuse rate of over 80%.

2、Energy Efficiency and Customization: boben Modular Cleanroom Manufacturers designs systems with variable-frequency ventilation and high-efficiency sealing. This can reduce operational energy consumption by 25% to 30% compared to traditional setups—a vital factor for long-term cost control in Southeast Asia.

3、Low Construction Barriers: Modular designs simplify the installation process. Local teams can often complete the assembly with basic training or video guidance, mitigating the shortage of specialized high-end construction labor.

3.Modular vs. Portable Cleanrooms: A Comparison

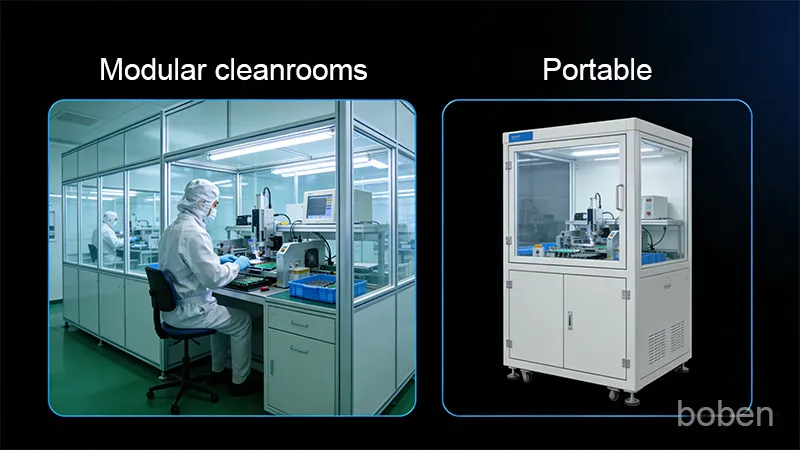

The Vietnamese market utilizes both modular and portable solutions to cover different operational scales.

| Feature | Modular Cleanrooms | Portable Cleanrooms |

| Scale | Large-scale (10㎡ to 1,000+㎡) | Small-scale (Localized booths) |

| Structure | Rigid frame, multi-zone design | Flexible “tent-style” or rapid-setup |

| Cleanliness | ISO Class 5 to 8 | ISO Class 7 to 8 |

| Best For | Full production lines, pharma workshops | Lab testing, temporary repairs, small assembly |

| Customization | High (ESD, Precision T/H, anti-vibration) | Low (Standardized dimensions) |

While modular systems provide a permanent feel for large-scale operations, portable units offer agility for SMEs with limited budgets or temporary cleanliness needs.

4.Key Beneficiary Industries in Vietnam

4.1. Electronics and Semiconductors

With giants like Samsung and Intel operating in Vietnam, the demand for ISO Class 5-6 environments is critical. Custom solutions from boben Modular Cleanroom Manufacturers specifically address the challenges of Southeast Asia’s high humidity, ensuring stable temperature and humidity control for sensitive PCB and chip packaging processes.

4.2. Medical Devices and Pharmaceuticals

Vietnam’s domestic medical manufacturing sector is under pressure to meet international GMP standards. Modular cleanrooms provide sterile production spaces with minimal construction-related contamination, allowing existing plants to upgrade without halting operations.

4.3. Food Processing and Packaging

For the export of aquatic products, dried fruits, and baked goods, hygiene is paramount. Cleanrooms effectively control microbial levels, ensuring food safety and helping Vietnamese brands meet the import standards of the global market.

4.4. Precision Machinery

In the automotive and hardware sectors, modular cleanrooms isolate dust and metallic debris. This prevents contamination during the machining of high-precision parts, directly improving the product’s competitive edge and final yield.

Modular cleanrooms have become a cornerstone of industrial upgrading in Vietnam. Their efficiency, flexibility, and cost-effectiveness align perfectly with the needs of a rapidly evolving manufacturing landscape. By providing localized, high-performance solutions, boben Modular Cleanroom Manufacturers continues to empower Vietnamese enterprises to enhance product quality and compete on the global stage.

As the region moves toward even higher levels of technological sophistication, the application of modular cleanroom technology is expected to expand, driving further innovation across Southeast Asian supply chains.