boben

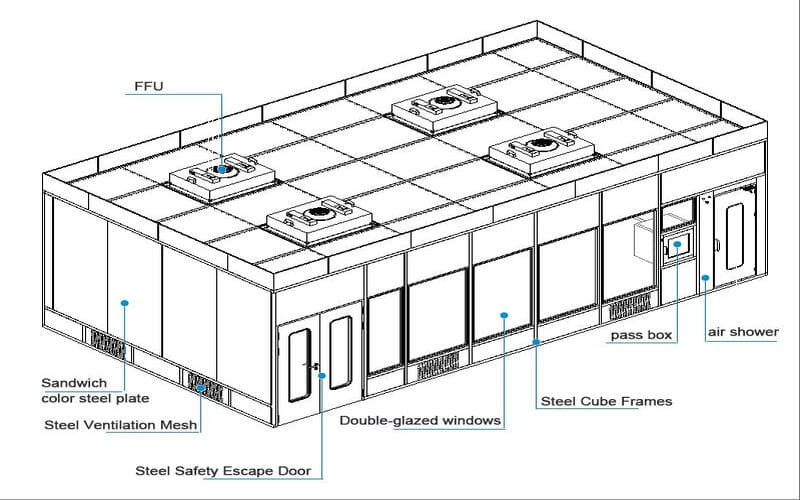

Modular Cleanrooms

Shorten Your Project Cycle by 60% and Achieve ISO/GMP Compliance with Ease

Highlights of our Modular Clean Room

Go beyond your project list with truly unique experiences. Enjoy quiet, safe, andpure clean in our modular cleanroom.Reduced Project Timelines

Rapidly ramp up production to seize market opportunities

Construction efficiency is 80% higher than traditional methods, featuring factory prefabrication and rapid on-site assembly without complex civil engineering.

Flexible Asset Appreciation

Supports expansion and relocation with 100% investment protection

98% of materials are reusable, allowing for flexible disassembly and reassembly or (with optional casters) complete relocation.

Costs are transparent and controllable

Budget stability, reducing long-term operational and maintenance costs

Standardized production reduces manufacturing costs, and future expansion requires no dismantling or modification, minimizing secondary investments and resource waste.

Intelligent Precision Management

Real-time control of environmental parameters doubles operational efficiency.

boben PLC Smart System: One-touch adjustment of airflow, pressure differential, and temperature/humidity ensures stable operating conditions.

Free Desiqn

We can provide you with targeted design solutions for various production environments or industries, free of charge.

IS0 4-9 Class

Create a cleaner production space, FFU creates a class ISO 4-9 clean space.

Fast Installation

Modular design, 3-7 days fast installation, and easy to expand.

Wide Application

Perfect for lab, medical, pharmaceutical, semiconductors, and aerospace manufacturing.

With our experiences you always get sucess

Professional

20 years of industry history gives us rich experience and knowledge.

With a local expert

We will arrange experts to serve at your project location until all problems solved.

Without delay

Our projects are always completed ahead of schedule, get you more time for others.

Four Pillars

Ultra-High-Efficiency Purification Core: FFU Fan Filter Unit

Equipped with premium energy-efficient, low-noise fans (or specified renowned brands) to ensure uninterrupted, highly stable clean airflow. The enclosure utilizes galvanized aluminum-zinc sheet/stainless steel material for corrosion and moisture resistance. Cleanliness levels can be customized to meet requirements, covering the full range from ISO Class 3 (Class 100) to ISO Class 8 (Class 300,000).

Robust Frame System: Customizable materials for harsh environments

Stainless steel frame: Suitable for demanding environments such as pharmaceutical and chemical industries where extremely high corrosion resistance and strength are required.

Aluminum alloy frame: Lightweight and efficient, quick to install, with a sleek and sophisticated appearance that balances aesthetics and functionality.

Walls and Ceilings: Diverse Materials to Meet Special Requirements

Wall Material Selection:

boben Exclusive Smart Control System

Our proprietary PLC-based intelligent control system enables integrated management and real-time monitoring of environmental parameters such as FFU air velocity, pressure differential, and temperature/humidity (requires compatible air conditioning), ensuring stable and controllable conditions within your cleanroom.

Parameters

| Cleanliness Level | Particle size (micrometers) | Maximum Allowable Particulate Matter Concentration (Particles/m³) | Temperature Range (°C) | Humidity Range (%) | Pressure difference (Pa) |

| ISO 5 (Class 100) | ≥0.5 | 3,520 | 20-24±2 | 45-60±5 | 10-30 |

| ISO 6 (Class 1000) | ≥0.5 | 35,200 | 20-26±2 | 40-65±5 | 10-20 |

| ISO 7 (Class 10000) | ≥0.5 | 352,000 | 18-28±3 | 30-70±10 | 5-15 |

| ISO 8 (Class 100000) | ≥0.5 | 3,520,000 | 18-30±3 | 30-75±10 | 5-10 |

Act Now:Customize Your Rapid Clean Space!

Don’t let lengthy lead times slow down your production schedule.Contact our cleanroom experts for a free design consultation and customized quote to kickstart your fast-track production journey.