Get a quoate

Fume Hood vs. Laminar Flow Cabinet: What’s the Difference?

Published : 2026-02-01With years of experience in cleanroom equipment outfitting, we hear the same question from clients almost every day: “Fume hoods and laminar flow cabinets look similar—which one should I choose?”

It is a common point of confusion. We have even seen clients purchase the wrong equipment based on appearance alone, resulting in wasted budget, rework, and project delays. Today, let’s skip the jargon and get straight to the facts. We will explain the core differences, analyze real-world scenarios, and show you how Boben Modular Cleanroom Manufacturers customizes solutions to help you make the right choice the first time.

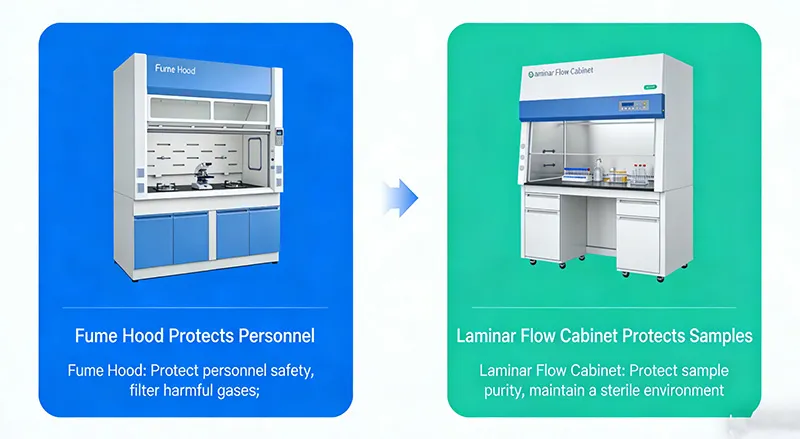

The Golden Rule: The Core Difference

If you remember only one thing, make it this: A Fume Hood protects the Human. A Laminar Flow Cabinet protects the Sample.

This single sentence is your most critical guide. The confusion often stems from not understanding this fundamental logic:

- Fume Hoods isolate harmful substances to protect the operator.

- Laminar Flow Cabinets purify the air to protect the product/sample.

A single word makes a world of difference in application.

Fume Hoods: The “Exhaust System” (Protecting the Operator)

Core Function: Removing toxins. Target Scenario: Operations involving toxic gases, dust, or volatile reagents (e.g., chemical labs, pharmaceutical reagent handling, chemical testing).

How it Works: A fume hood typically relies on an external roof-mounted fan to create a negative pressure environment. It acts like a powerful vacuum, sucking toxic gases and corrosive vapors generated during operations into the cabinet and exhausting them outdoors through a dedicated duct system.

- Safety First: It ensures harmful substances never drift toward the operator.

- Priorities: It doesn’t prioritize high cleanliness; its focus is sealing and exhaust efficiency—locking the toxins in and getting them out.

2.Laminar Flow Cabinet: The “Clean Bench” (Protecting the Sample)

Core Function: Dust and contamination prevention. Target Scenario: Operations requiring extreme cleanliness (e.g., microbiology, sterile compounding, electronics assembly, cell culture).

How it Works: Also known as a Clean Bench, this unit features a built-in fan that draws room air in and forces it through a HEPA filter (removing 99.97% of particles at 0.3μm). It then blows this purified air in a uniform, unidirectional stream (laminar flow) across the work surface.

- Product Safety: It creates a sterile, dust-free zone that prevents airborne particles or microbes from landing on your sample.

- Priorities: It focuses on cleanliness (ISO Class 5 / Class 100) and stable airflow. It typically uses internal circulation and does not require external exhaust ducts.

Boben’s Integrated Strategy: Using Both Together

In actual cleanroom construction, many facilities require both devices. This is a standard configuration provided by Boben Modular Cleanroom Manufacturers.

Case Study: Pharmaceutical Aseptic Lab

- Step 1 (Reagent Prep): The process involves volatile, harmful chemicals. Boben installs a Fume Hood here to protect the staff from inhaling fumes.

- Step 2 (Sterile Filling/Testing): The process requires a contaminant-free environment. Boben installs a Laminar Flow Cabinet here to ensure the samples remain pure and data remains accurate.

This dual approach meets industry compliance while balancing personnel safety with experimental precision.

Key Operational Differences

| Feature | Fume Hood | Laminar Flow Cabinet |

| Sash (Glass Door) | Keep Low: Only open enough for hands to enter to prevent fume leakage. | Keep Open: Designed to allow clean air to flow over the work area unrestricted. |

| Maintenance | Duct Check: Regularly check exhaust ducts for blockages to prevent backflow. | Filter Change: Regularly replace HEPA filters to maintain sterility. |

| Airflow Direction | Suction: Pulls air away from the user. | Blowing: Blows clean air toward the user/sample. |

The Danger of Mixing Them Up

The biggest mistake clients make is swapping these units.

- Risk 1: Using a Laminar Flow Cabinet for chemical experiments.

Result: The cabinet blows toxic fumes directly into the operator’s face. This is a major safety hazard.

- Risk 2: Using a Fume Hood for sterile microbiology.

Result: Dirty room air is drawn over the sample, causing contamination and failed experiments.

Still Unsure? Ask the Experts.

If you are still struggling to decide, don’t guess. Boben Modular Cleanroom Manufacturers offers free site survey services.We analyze your industry, specific operational needs, and compliance standards to recommend the exact equipment you need—whether it’s a Fume Hood, a Laminar Flow Cabinet, or a combination of both. Our goal is to provide a custom solution that solves your pain points without wasting budget.