Get a quoate

What is a Fume Hood? Functions, Benefits & Proper Usage Guide

Published : 2025-12-29I. Core Concept Decomposition of a Fume Hood

A fume hood is a core safety protection device in laboratories, industrial production, and other scenarios. Essentially, it is an enclosed operating space with directional exhaust functions. By establishing stable airflow organization, it achieves the isolation and discharge of hazardous media within the operating area. Its core components include the Cabinet Body (providing an enclosed workspace), Exhaust System (including fans and ducts as core power components), Air Inlet/Airfoil Structure (ensuring airflow stability), Control Panel (regulating air volume and monitoring status), and the Sash (safety glass door separating the operator from hazardous media).

Deconstructing its function, the core role of a fume hood revolves around “Protection” and “Purification,” which can be divided into three sub-dimensions:

- Direct Protection for Personnel: Preventing operators from inhaling or contacting hazardous media.

- Protection of the Environment: Preventing hazardous media from diffusing and contaminating the overall room.

- Process Assurance: Maintaining a stable micro-environment in the operating area to ensure the process is safe and controllable.

II. Common FAQs Regarding Fume Hoods

Q1: Can fume hoods only exhaust hazardous chemical gases?

A: No. The core function of a fume hood is to discharge various hazardous media generated during operations. Besides common harmful gases from chemical experiments (such as Formaldehyde, Benzene, Chlorine, etc.), it can effectively exhaust Dust (e.g., solid powder from grinding, metal dust in industrial production), Fumes (e.g., metal fumes from welding, smoke from burning samples), and Aerosols (e.g., bacteria-laden aerosols in biological experiments). The key lies in using stable negative pressure airflow to confine suspended or diffusing hazardous media within the cabinet and discharge them promptly. Different types of fume hoods (e.g., Acid-Resistant, Explosion-Proof, Biological Safety) are optimized for different media characteristics, but the core function of expulsion and isolation is universal.

Q2: Does turning on the fume hood guarantee 100% operational safety?

A: No. The protective function of a fume hood relies on correct usage and normal operation; it cannot guarantee absolute safety on its own.

- System Failures: If the airflow is insufficient, ducts leak, or the fan fails, negative pressure is lost, and hazardous media may escape.

- Improper Operation: Actions such as sticking one’s head into the hood, opening the sash too high, or performing hazardous operations outside the hood will disrupt airflow stability and reduce protection.

- Extreme Hazards: For highly toxic or highly corrosive substances, a fume hood must be used in conjunction with Personal Protective Equipment (PPE), such as gas masks and chemical suits. Therefore, the fume hood is a vital part of the safety system, but not the only guarantee.

III. Core Benefits of Using Fume Hoods Correctly

- Ensuring Personnel Health and Safety This is the most critical benefit. By promptly exhausting toxic gases, dust, and fumes, it prevents operators from inhaling harmful substances and reduces the risk of skin contact. This lowers the probability of occupational diseases (such as respiratory diseases and chemical burns) at the source, serving as a key barrier in high-risk industries like chemistry, biology, and metallurgy.

- Maintaining Environmental Cleanliness and Stability Fume hoods confine hazardous media to a local space and exhaust them, preventing diffusion into the general laboratory or production workshop. This protects indoor air, equipment, and samples from contamination. Simultaneously, stable airflow maintains micro-environmental parameters (like temperature and humidity) in the operating area. This aligns perfectly with the clean environment philosophy advocated by Boben Modular Cleanroom Manufacturers, providing excellent conditions for precision experiments and production.

- Reducing Safety Accident Risks For volatile, flammable, and explosive media, fume hoods prevent the concentration of indoor gases from reaching explosive limits, thereby reducing the occurrence of fires and explosions. For corrosive media, they prevent diffusion that could corrode equipment or damage building structures, reducing the risk of facility failure.

- Meeting Compliance Requirements In research and industrial sectors, regulations (such as Laboratory Safety Standards and Industrial Hygiene Standards) have clear requirements for handling hazardous media. Rational use of fume hoods is a necessary condition for compliance, helping enterprises avoid penalties for violations while improving overall safety management levels.

IV. Detailed Steps to Maximize Fume Hood Functionality

1. Pre-Use Preparation

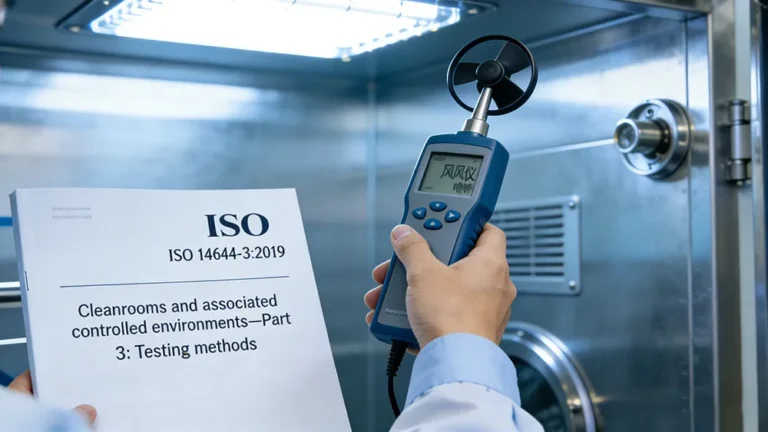

- Check Status: Use the control panel to confirm the fan is running normally. Check if the air volume data is within the required range (usually a Face Velocity of 0.5–1.0 m/s). Ensure the sash moves smoothly and seals well.

- Clear Area: Remove unrelated items from the hood to ensure the airflow path is unobstructed. Check duct connections for leaks.

- Pre-Run: Turn on the fume hood 10–15 minutes in advance to establish a stable negative pressure environment.

2. Standard Operating Procedures

- Sash Adjustment: Generally, keep the sash opening height below 20 cm (or at the marked working height) to allow hand access while maintaining stable negative pressure.

- Placement: Place apparatus generating hazardous media (e.g., reactors, beakers, grinders) deep inside the hood, away from the air inlet to avoid blocking the airflow channel.

- Body Position: Keep hands and body away from the sash opening as much as possible. Avoid rapid limb movements that disrupt airflow. If adding reagents or adjusting equipment, move slowly and steadily.

- Airflow Adjustment: If a large amount of hazardous media is generated (e.g., gas from violent reactions, heavy dust), increase the air volume via the control panel to ensure timely exhaust.

3. Post-Use Processing

- Delay Shutdown: Do not turn off the fume hood immediately after operation. Let it run for another 5–10 minutes to ensure residual hazardous media is completely exhausted.

- Cleaning: Remove waste and residual reagents promptly. Wipe the interior with a dedicated cleaner to prevent corrosion from residues.

- Shutdown: Close the sash and turn off the hood via the control panel (or keep it in standby mode for continuous scenarios). Log the run details (time, air volume data, anomalies).

4. Routine Maintenance

- Weekly Checks: Inspect air volume and sealing performance. If airflow is insufficient or seals are loose, contact maintenance immediately.

- Monthly Cleaning: Clean ducts and fan filters to prevent dust accumulation from affecting exhaust efficiency.

- Training: Regularly train operators. Boben Modular Cleanroom Manufacturers suggest incorporating fume hood maintenance into the overall clean environment management system to avoid performance degradation due to improper use.

V. Practical Case Study Results

Case 1: University Chemical Laboratory Before using fume hoods, indoor concentrations of hazardous gases like Formaldehyde and Toluene frequently exceeded safety standards during organic synthesis experiments (Formaldehyde limit > 0.1 mg/m³), causing dizziness and respiratory discomfort among researchers. After introducing corrosion-resistant fume hoods and enforcing standard usage, hazardous gases were exhausted effectively. Indoor concentrations stabilized below safety limits, symptoms disappeared, and the laboratory safety inspection pass rate rose from 65% to 100%.

Case 2: Electronic Component Production Workshop A chip soldering process generated lead smoke and solder fumes. Previously relying on standard exhaust fans, the workshop suffered from excessive dust (PM2.5 > 0.075 mg/m³), dust accumulation on equipment affecting quality, and high rates of respiratory abnormalities in employee health checks. The workshop partnered with Boben Modular Cleanroom Manufacturers to install dedicated industrial fume hoods and a modular cleanroom system. All soldering operations were moved inside the hoods. Result: PM2.5 stabilized below 0.03 mg/m³, product yield increased from 92% to 98.5%, and employee health anomalies dropped by 80%.

Case 3: Biological Laboratory While handling bacteria-laden samples during microbial culture and testing, the lab previously did not use fume hoods, leading to biological aerosol diffusion risks and prior incidents of staff infection. After equipping the lab with Biosafety Fume Hoods, all sample handling was confined within the cabinet. The negative pressure environment effectively isolated biological aerosols. No further infections occurred, and the sample cross-contamination rate dropped from 5% to 0.3%, significantly improving data accuracy.