Get a quoate

When to Use a Fume Hood: The Ultimate Laboratory Safety Guide

Published : 2025-12-26In laboratory planning and daily operations, a Fume Hood is far more than just a piece of furniture—it is the “first core line of defense” protecting the lives of researchers. Many managers and operators often wonder: Which experiments must be conducted inside a fume hood? When is it safe to operate on a standard bench? This article provides a deep dive into this critical question.

I. What is the Standard for Judging “When to Use”?

To judge “when to use,” one must first understand the three core mechanisms of a fume hood, which dictate its applicable scenarios:

- Capture at Source: Utilizing aerodynamic principles, fume hoods use negative pressure generated by centrifugal or axial fans to instantly capture toxic gases, vapors, or dust before they diffuse.

- Physical Isolation: Relying on a tempered glass sash and a full-steel body, it establishes a sturdy physical barrier between the operator and dangerous chemical reactions, preventing injuries from chemical splashes or minor explosions.

- Controlled Disposal: Through top-mounted vents and PVC/flexible ducting systems, contaminants are directionally exhausted outdoors or through filtration systems, rather than circulating within the laboratory.

In short: If an experiment involves volatility, corrosiveness, toxicity, or potential explosion risks, it is time to use a fume hood.

II. Common FAQs Regarding Usage Scenarios

Q1: My lab is already equipped with central air conditioning and exhaust fans. Do I still need to work inside a fume hood?

A: Absolutely. Central air conditioning and standard exhaust fans only serve to “dilute” indoor air; they cannot prevent high-concentration toxins from being inhaled by personnel before dilution occurs. The role of a fume hood is “point-source elimination,” locking contaminants inside the cabinet before they reach the operator’s breathing zone—something general ventilation cannot replace.

Q2: Must all experiments involving liquids be done in a fume hood?

A: No. If the experiment involves only non-toxic, odorless, non-volatile reagents (such as mixing pure water or saline solutions), it can be performed on a standard bench. However, once the experiment involves acids/alkalis (requiring corrosion-resistant lining), organic solvents (highly volatile), or unknown reaction byproducts, it must be conducted inside a fume hood.

III. The Benefits of Correct Judgment and Usage

- Achieve Ultimate Safety (Zero Leakage): Correct usage timing combined with high-performance fume hoods (e.g., products with zero-leakage airflow designs) ensures a 100% capture rate of hazardous gases, protecting researchers from occupational diseases.

- Reduce Operational Energy Costs (Cost Saving): Distinguishing usage scenarios maximizes the value of VAV (Variable Air Volume) systems. When exhaust is not needed, the system runs at low speed; when the sash is lowered for dangerous operations, the system automatically adjusts airflow, saving up to 50% on air conditioning energy consumption.

- Extend Equipment Life & Ensure Compliance: Handling corrosive substances inside the hood utilizes its corrosion-resistant sink and phenolic/ceramic lining, preventing corrosive gases from damaging expensive lab instruments and decor. It also ensures compliance with ASHRAE or EN safety audit standards.

IV. Step-by-Step Guide: How to Do It Right

When you determine that a fume hood is necessary, strictly follow this Standard Operating Procedure (SOP):

- Step 1: Startup & Self-Check Turn on the multi-functional LCD control panel. Check the display data to confirm the fan is running normally, the face velocity is within the safe range (usually 0.5m/s), and there are no audio-visual alarms.

- Step 2: Equipment Placement (The 15cm Rule) Place experimental equipment at least 15cm deep from the sash edge. Ensure large equipment does not block the rear baffles or the bottom air inlets to avoid blocking airflow and causing turbulence.

- Step 3: Sash Adjustment & Operation During operation, pull the tempered glass sash down to the marked safety height (usually below the operator’s breathing zone). Minimize rapid, large arm movements inside the hood to prevent disturbing the airflow and causing leakage.

- Step 4: Post-Experiment Process Do not turn off the fan immediately after the experiment. Let the fan run for another 5-10 minutes (or use the “delay off” function on the panel) to thoroughly purge residual fumes from the ductwork, then close the sash to save energy.

V. Real-World Value: Case Studies

- Result 1: Neutralizing Sudden Dangers During a synthesis reaction in a university chemistry lab, a flask accidentally burst, spraying strong acid. Because the operator strictly followed regulations and worked inside the fume hood, the tempered glass sash completely blocked the splashing liquid, and the PP corrosion-resistant sink collected the waste. No personnel were injured, avoiding a serious medical accident.

- Result 2: Significant Energy Savings A pharmaceutical company introduced smart fume hoods adapted for VAV systems. Employees only activated high-exhaust modes when involving volatile solvents, running low volumes otherwise. A one-year review showed a decrease in overall laboratory HVAC energy costs by over 40%.

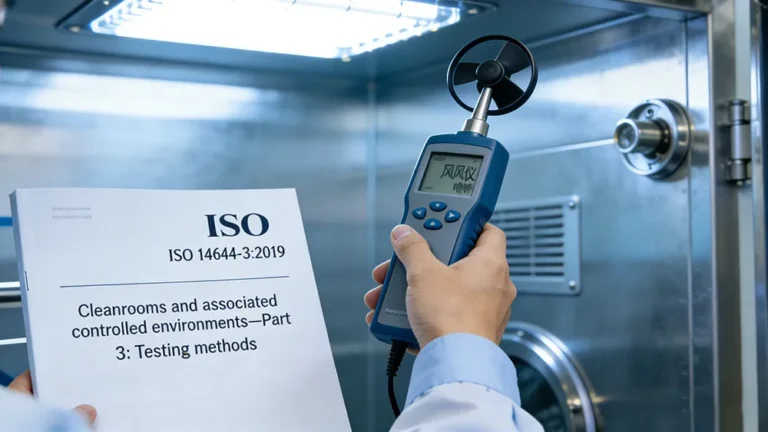

- Result 3: Resolving Odor Complaints A testing agency was previously cited by environmental authorities due to the long-term presence of organic solvent odors. After moving all volatile operations into high-performance fume hoods equipped with centrifugal fans, indoor air quality indicators quickly met standards, odors vanished completely, and the facility successfully passed ISO environmental system certification.

It is important to note that fume hoods are not “universal protection.” When in use, ensure the hood sash is opened within the safe range, minimize reaching inside the hood during operations, and maintain proper ventilation system operation. Only through proper and timely use of fume hoods can their protective functions be fully realized. Remember, safety is the foundation of experimental innovation. Every compliant use of a fume hood represents a solemn commitment to the safety of yourself and others.