Get a quoate

Why Air Showers are Essential for Modular Cleanroom Efficiency

Published : 2025-12-21In industries such as electronics, pharmaceuticals, and food processing, the cleanroom is the core guarantee of product quality. The Air Shower serves as the critical “first line of defense.”

When constructing cleanrooms—especially Modular Cleanrooms—enterprises often wonder if an air shower is truly necessary. Beyond simply “blowing off dust,” an air shower intercepts pollution at the source, stabilizes cleanliness levels, reduces operating costs, and complements the flexibility of modular designs.

1. Source Control: Reducing Product Defect Rates

Personnel and materials are the primary sources of contamination. Even in ISO Class 8 cleanrooms, a single employee’s clothing may carry over one million particles (≥0.5 microns), which can cause microelectronic components to short circuit or lead to microbial contamination of food and pharmaceutical products.

- High-Speed Decontamination: Air shower systems utilize high-speed HEPA-filtered air (20-25 meters per second) to flush surface particles.

- Proven Results: Research shows that air showers can reduce personnel-induced contamination by over 85%.

- Case Study: After installing air shower systems, an electronics factory reduced circuit board scrap rates from 3.2% to 0.8%, saving over $7,000 (approximately ¥50,000) in monthly costs.

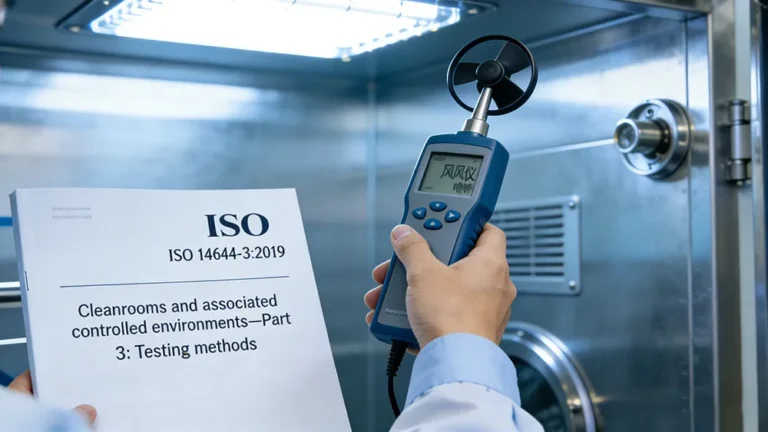

2. Compliance & Stability: Ensuring Certification Success

Whether it is GMP certification for pharma or ISO 14644 for electronics, maintaining a stable cleanliness grade is the key to passing audits.

- Pressure and Isolation: The air shower device functions as an airlock, preventing the escape of clean air and the influx of contaminated air, thereby maintaining a critical positive pressure differential (typically ≥5 Pa).

- Pressure and Isolation: The air shower device functions as an airlock, preventing the escape of clean air and the influx of contaminated air, thereby maintaining a critical positive pressure differential (typically ≥5 Pa).

Comparison: With vs. Without Air Shower

| Key Parameter | With Air Shower | Without Air Shower |

| Particle Concentration | Stable; minimal fluctuations during entry | High spikes during personnel shifts |

| Pressure Differential | Stable (Airlock protection) | Fluctuates; risk of external air inflow |

| Audit Compliance | High; meets GMP/ISO standards easily | Risky; prone to failure during dynamic testing |

| Filter Lifespan | Extended (Primary filters last 30% longer) | Shortened due to heavy dust load |

3. Cost Efficiency & Modular Compatibility

While there is an initial investment, an air shower is a “money-saver” in the long run:

- Lower Maintenance: By removing the bulk of contaminants at the door, the load on the main HVAC/FFU (Fan Filter Unit) system is significantly reduced, extending the life of expensive HEPA filters by over 30%.

- Rapid Deployment: Modular air showers follow the “factory-prefabricated, onsite-assembly” logic.

- Efficiency Example: A food processing plant integrated a modular air shower with their modular cleanroom. The total installation took only 20 days—40 days faster than traditional civil construction—allowing for much earlier production and ROI.

4. Personnel Management: Cultivating a “Clean Culture”

The air shower serves as a physical and psychological gateway:

- Standardized Protocols: Equipped with infrared sensors and electronic interlocks, the system forces a mandatory spray cycle (usually 10–30 seconds), preventing staff from skipping hygiene steps.

- Awareness: It acts as a constant reminder to employees that they are entering a controlled environment, reinforcing strict adherence to cleanroom protocols.

Selection Guide & Conclusion

Air showers are suitable for almost all controlled environments. When choosing a unit, consider the following:

1.Traffic Volume: High-traffic areas should use “Double-Person” or “Tunnel” air showers.

2.Material Flow: Use Cargo Air Showers (with floor tracks or wide doors) for equipment and supplies.

3.Construction Type: For modular cleanrooms, always opt for pre-fabricated modular air showers to ensure perfect structural matching.

An air shower is not an “optional add-on” but a fundamental component for safeguarding quality and reducing operational risk. By integrating an air shower, you build a robust barrier that protects your products, your equipment, and your bottom line.