Get a quoate

A Small Modular Cleanroom Medical Equipment Calibration Laboratory in Jeddah, Saudi Arabia

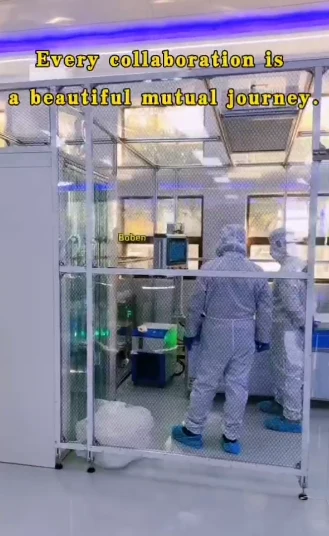

Published : 2025-12-15This is a case study of a small modular cleanroom medical equipment calibration laboratory in Jeddah, Saudi Arabia. The client specializes in precision calibration but lacked space for new calibration equipment. They repurposed a storage room adjacent to their clinic into a cleanroom. However, the storage room measured 8m long × 5m wide with a ventilation duct protruding from the ceiling. Additionally, it had to meet Saudi Arabia’s Ministry of Health (MOH) cleanliness standards for medical laboratories. The timeline was extremely tight: the lab had to be operational one week before the Hajj season, or the medical equipment orders would be lost.

We at boben Modular Cleanroom Manufacturers first had the client video the ductwork layout in the storage room. We pre-cut the frame to “non-standard dimensions avoiding the ductwork.” For wall panels, we selected flame-retardant EPS boards suitable for Saudi Arabia’s high-temperature environment. Seals were upgraded to fluororubber rated for 55°C—after all, Jeddah summers can reach 48°C indoors without AC, where standard silicone fails.

When shipping components to Jeddah Port, we pre-prepared the material compliance certificates required by the Ministry of Health (MOH), ensuring smooth customs clearance and delivery to the site within three days. Local workers had no experience installing irregular modular frames, so we conducted daily video supervision for five consecutive days after work hours (after 4 PM Saudi time). Key instructions included: frames must leave a 10cm gap alongside pipes, and air shower wiring must match local three-phase power.

Including space reserved for calibration equipment, installation wrapped up in 10 days. When MOH inspectors measured the cleanliness level, it hit the exact ISO 7 standard.

the client’s lab director sent a WhatsApp voice message that day, his voice clear: “We thought converting the storage room was impossible, but boben even accounted for the pipe clearance! Now our monitor calibration orders have tripled, and the equipment is running nonstop.”

If you have a similar need in Saudi Arabia—converting a space into a cleanroom while rushing to meet peak season orders—contact us with your site dimensions and industry. We’ll promptly provide a customized quotation.