Get a quoate

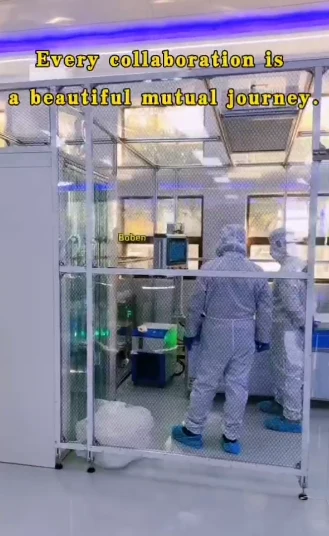

Singapore Testing Laboratory Clean Booth Case Study: Temporary Clean Zone Erected in 3 Days

Published : 2025-12-15This is a real-world clean booth project for a small COVID-19 residue testing lab in Singapore: After securing community screening contracts, the client faced insufficient clean area capacity. Located in an aging downtown office building, the lab could not alter existing finishes while still meeting Singapore’s SS 536 cleanliness standards—all within a four-day timeline.

The Challenges Were Real:

- Space Constraints: The lab is located in an older office building in Singapore’s city center. The space is extremely tight, and the existing renovation could not be altered.

- Strict Compliance: The facility had to meet the local Singapore Standard SS 536 (Code of Practice for Safety in Laboratories); otherwise, it would not pass the National Environment Agency (NEA) inspection.

- Extreme Urgency: Orders were scheduled to start the following week, leaving us a maximum window of 4 days.

Boben Solutions: The modular cleanroom manufacturer immediately requested the client to provide a panoramic video of the site. The target area is a 6m × 4m corner with ventilation ducts and fire sprinkler systems suspended from the ceiling.

- Structure: We opted against fixed walls, using an aluminum profile frame for quick assembly.

- Enclosure: We selected anti-mildew PVC strip curtains as partitions. Note: Since Singapore’s humidity is constantly above 80%, we specifically upgraded these to an anti-bacterial model.

- Airflow: The High-Efficiency Particulate Air (HEPA) supply outlets were strategically positioned to bypass the ceiling pipes.

Execution & Delivery: The components shipped from China and cleared Singapore customs in just 2 days. The client hired two local contractors, and we supported them with a synchronized approach:

1.Step-by-Step Videos: Sent in advance for preparation.

2.WhatsApp Live Support: We monitored the installation via video call in real-time. Crucial Adjustment: We guided them to lower the frame height by 20cm to clear the fire sprinklers and ensured the soft curtains had a 10cm ground overlap to prevent air leakage.

The Results: The entire installation was completed in just 3 days. On the same day, we remotely guided them to use a particle counter for testing.

- Cleanliness Level: Achieved ISO Class 8.

- Compliance: Perfectly met SS 536 requirements.

The Lab Supervisor later messaged us: “I was worried a temporary booth wouldn’t be compliant, but the Environment Agency officer passed it immediately. We are now handling an extra 200 test orders every day.”

Do you have a need to add a temporary clean area in a small space in Singapore?

Contact us with your site dimensions + industry. I will send you the Material List for this exact Clean Booth model, along with a Singapore Local Compliance Guide.