Get a quoate

What are the different types of clean room panels?

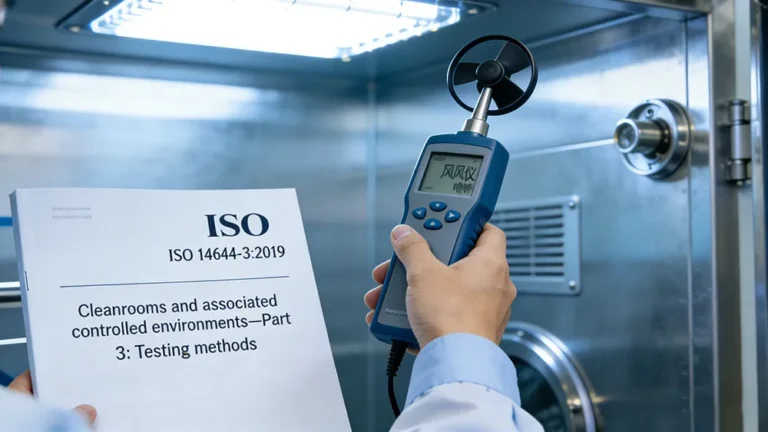

Published : 2025-11-27The cleanliness effectiveness of a cleanroom relies not only on filtration systems and sealing designs, but also on the core enclosure material—the panels—which directly impact critical performance aspects like dust resistance, microbial protection, and ease of cleaning. Choosing the right cleanroom panels can prevent future issues like dust accumulation and corrosion while reducing maintenance costs. But with so many panel types on the market, how do you choose? Today we break down four mainstream cleanroom panel types to help you precisely match your needs. Meanwhile, boben Modular Cleanroom Manufacturers has already developed highly adaptable panel solutions tailored for diverse scenarios, becoming the trusted choice for numerous enterprises.

The first type is color-coated steel panels, considered the “cost-effective choice” for cleanrooms. Featuring a sandwich-core color-coated steel structure with anti-static and antibacterial surface coatings, these panels incorporate rock wool or polyurethane insulation for superior sealing, thermal efficiency, and fire resistance. Installation is straightforward, with seamless joint sealing via sealant that resists dust accumulation. Daily cleaning requires only a quick wipe, making them suitable for Class 100,000 to Class 10,000 cleanrooms. Common applications include electronics assembly, food processing, and general laboratories. With years of industry expertise, boben Modular Cleanroom Manufacturers understands the core requirements for panels across different scenarios. We recommend suitable color steel panels based on your cleanliness level and operating environment, ensuring performance while controlling costs.

The second option is stainless steel panels, emphasizing “corrosion resistance and high cleanliness.” Constructed from 304 or 316L stainless steel with mirror-polished surfaces, these panels feature zero pores and resist dust adhesion. They withstand chemical disinfectant corrosion and remain undamaged even with frequent cleaning. This panel type is the preferred choice for biopharmaceuticals, sterile preparations, and high-end semiconductor manufacturing—such as vaccine production facilities requiring prolonged disinfectant exposure. Stainless steel panels ensure a sterile environment free of residues. boben Modular Cleanroom Manufacturers rigorously controls panel material selection. Whether it’s the coating adhesion of color-coated steel panels or the polishing precision of stainless steel, all meet international standards. This ensures panels remain intact and dust-free over extended use, safeguarding the cleanroom’s first line of defense. The third option is aluminum honeycomb panels, representing the pinnacle of “lightweight yet high-strength” solutions. Featuring an aluminum honeycomb core sandwiched between aluminum alloy skins, these panels weigh only one-third of traditional alternatives while delivering exceptional compressive strength, sound insulation, and thermal performance. Their advantage lies in suitability for large-scale cleanroom construction, such as Class 1000+ electronics factories and major research laboratories. They reduce structural load while delivering high flatness post-installation for a clean visual appearance. Recyclable and aligned with green production principles, these panels further enhance construction efficiency and shorten project timelines when paired with boben Modular Cleanroom Manufacturers’ modular assembly techniques. The fourth option is glass-reinforced magnesium oxide panels, designed for “fireproofing and moisture resistance.” Featuring a glass-reinforced magnesium oxide substrate with a fire-retardant coating, these panels offer a fire resistance rating of 1-2 hours while providing excellent moisture resistance, preventing deformation and mold growth. This panel is suitable for environments with stringent fire safety requirements, such as chemical laboratories, lithium battery production workshops, and cleanrooms in high-humidity southern regions. Offering moderate cost and outstanding value, it ensures precise panel dimensions through boben Modular Cleanroom Manufacturers’ standardized production. The assembled panels achieve compliant sealing performance, preventing cleanliness degradation due to gaps. The core principle in selecting cleanroom panels is “scenario compatibility”: color-coated steel panels for general applications, stainless steel for high-cleanliness and corrosion-resistant environments, aluminum honeycomb panels for large-area lightweight needs, and magnesium oxide boards for fireproofing and moisture resistance. boben Modular Cleanroom Manufacturers not only supplies all types of premium panels but also provides integrated “panel + installation + sealing” solutions tailored to your industry specifics, cleanliness requirements, and budget. From panel material selection to on-site assembly, we maintain professional oversight throughout the process to ensure panels perfectly integrate with your cleanroom system, delivering long-term, stable performance. If you’re struggling with selecting cleanroom panels and concerned that the wrong choice could compromise cleanliness, consult Boben Modular Cleanroom Manufacturers. Our expert team will tailor solutions based on your specific requirements.

The third type is aluminum honeycomb panel, a prime example of “lightweight yet high-strength” construction. Featuring an aluminum honeycomb core sandwiched between aluminum alloy skins, it weighs only one-third of traditional panels while delivering outstanding compression resistance, sound insulation, and thermal performance. Its advantages lie in suitability for large-scale cleanroom construction, such as Class 1000+ electronics factories and major research laboratories. It reduces structural load-bearing pressure while delivering high surface flatness and a clean visual appearance after installation. This panel is also recyclable, aligning with green production principles. Combined with boben Modular Cleanroom Manufacturers’ modular assembly process, it further enhances construction efficiency and shortens project timelines.

The fourth option is magnesium oxide board panels, designed for fire and moisture resistance. Featuring a magnesium oxide substrate with a fire-retardant coating, these panels offer a fire resistance rating of 1-2 hours while providing excellent moisture resistance, preventing deformation and mold growth. They are ideal for high-fire-risk environments like chemical laboratories, lithium battery production facilities, and cleanrooms in humid southern regions. Magnesium oxide panels offer moderate cost with outstanding value. Combined with boben Modular Cleanroom Manufacturers’ standardized production, they ensure dimensional accuracy for each panel. Post-assembly sealing performance meets standards, preventing cleanliness degradation due to gaps.

Selecting cleanroom panels hinges on “scenario compatibility”: choose color-coated steel panels for standard environments, stainless steel for high-cleanliness and corrosion resistance, aluminum honeycomb panels for large-area lightweight solutions, and magnesium oxide boards for fireproofing and moisture resistance. Boben Modular Cleanroom Manufacturers not only provides premium panels across all types but also delivers integrated “panel + installation + sealing” solutions tailored to your industry specifics, cleanliness requirements, and budget. From material selection to on-site assembly, we maintain professional oversight throughout the process, ensuring seamless integration between panels and cleanroom systems for long-term, stable performance.

If you’re struggling with cleanroom panel selection and concerned about compromising cleanliness, consult boben Modular Cleanroom Manufacturers. Our expert team will provide complimentary selection guidance and customized solutions tailored to your specific requirements. Choosing the right panels lays the foundation for your clean space. With reliable products and expert service, boben Modular Cleanroom Manufacturers helps you avoid selection pitfalls, ensuring your cleanroom operates stably long-term to safeguard production and research.