Products

Featured products

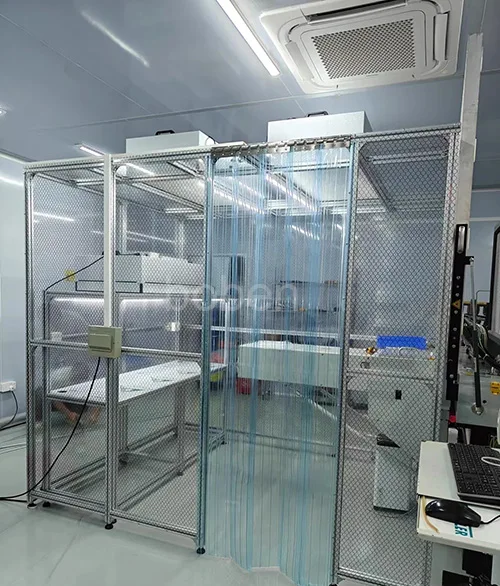

clean booth(Portable Cleanroom)

Compared to traditional cleanrooms, portable cleanrooms reduce investment costs by over 80%, with more economical consumables and operational energy consumption, delivering significant economic benefits. Clean booths install quickly and easily without complex infrastructure, becoming operational within 1-3 days, drastically shortening project timelines. Highly adaptable with customizable dimensions and adjustable cleanliness levels (Class 1-100,000), they support mobility and expansion. Ideal for pharmaceutical manufacturing, facility relocations, and similar scenarios.

Features:

Why Choose Our Mobile Cleanrooms?

- Our Clean Room Booth uses industrial aluminum or stainless steel frames with no welding required. Like building blocks, a Small Portable Clean Room can be assembled quickly by general technicians, significantly reducing labor and time costs.

- Whether you need a localized Clean Booth to cover a single machine or want to expand an existing clean area, our Mobile Cleanroom fits perfectly. With customizable sizes and anti-static curtains or acrylic panels, it deploys easily even in tight or irregular spaces.

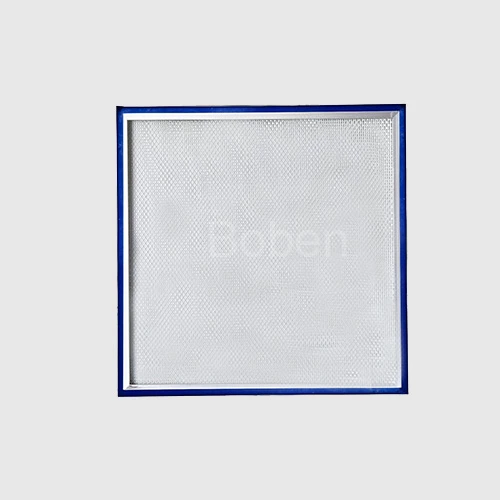

- Each unit is equipped with independent FFUs (Fan Filter Units) and HEPA/ULPA filters, achieving 99.99% efficiency @ 0.3μm. Operating independently of central HVAC, our Portable Clean Room offers lower energy consumption and precise control.

- Traditional cleanrooms are often scrapped during relocation, but our Clean Booth can be fully disassembled and reassembled. You can easily add modules to expand the area, ensuring a one-time investment with lifelong benefits.

Customized Solutions for Multiple Industries

With years of expertise in cleanroom technology, we provide Class 10-100,000 clean spaces for diverse industries.

Semiconductor/Electronics/Optoelectronics Industries

Semiconductor/Electronics/Optoelectronics Industries

Anti-static, high-grade filtration, modular expansion Medical Devices/Sterile Rooms

Medical Devices/Sterile Rooms

GMP-compliant, easy to disinfect, corrosion-resistant Higher Education/Research Laboratories

Higher Education/Research Laboratories

Precise temperature and humidity control, silent operation, quick assembly/disassembly

Engineering Case

Four core advantages, redefining clean production:

Cost: 50% investment savings, more economical operation

- Compared to traditional cleanrooms, the initial investment is directly reduced by more than 50%.

- Partial purification replaces full workshop purification, reducing energy consumption by 30% and making long-term operation more energy-efficient.

- Design to reduce material waste, high reuse rate, and significantly lower overall lifecycle costs.

- one million one hundred and eleven thousand one hundred and eleven.

Rapid deployment: Completed in 1-3 days, immediately put into production

Unlimited flexibility: customized according to needs, adjustable at any time

Excellent cleanliness: stable and reliable, quality assurance

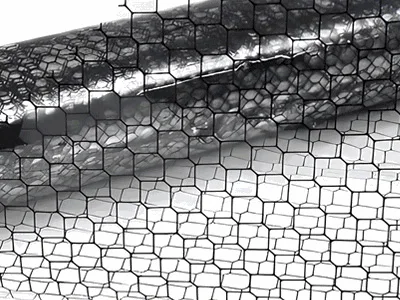

Anti-static Mesh Enclosures

Our mobile cleanrooms come standard with 0.5mm industrial-grade anti-static PVC mesh curtains. Not only do they offer exceptional transparency for easy observation, but they also employ advanced anti-static technology to create a dual protective barrier: effectively preventing dust adhesion while eliminating static hazards, ensuring your core equipment and sensitive components remain completely safe.

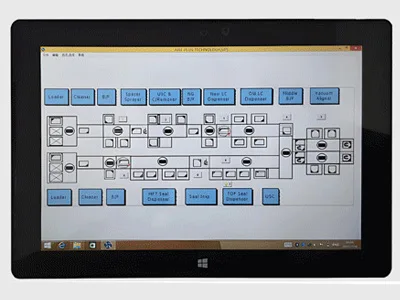

Digital-Intelligent Integrated Control System

The digital-intelligent integrated control module features an LCD touchscreen HMI with built-in PID constant airflow auto-regulation algorithms. The system delivers comprehensive smart functions: multi-speed fan control, differential pressure anomaly alerts, high-efficiency filter clogging alarms, and operational timers. Digital sensors provide real-time operational data feedback, ensuring the cleanroom consistently operates at optimal conditions.

Cleanroom-Specific LED Lighting

Features a streamlined LED lighting system designed specifically for cleanrooms. Its unique dust-free adsorption structure prevents particle accumulation, ensuring no interference with laminar airflow. This system delivers high lumen output with ultra-low power consumption and high color rendering index. Its scientifically calculated illuminance distribution fully complies with ISO and GMP standards for precision lighting in controlled environments.

Guaranteed Cleanliness Compliance

We commit to dual compliance assurance for every mobile cleanroom: High-frequency air sampling ensures particle counts strictly meet ISO-level standards. Combined with a high-volume air circulation system design, it guarantees optimal air changes per hour and wind speeds. At highly competitive pricing, we enable your project to deploy and commence production within minimal timelines, achieving a perfect balance of safety and efficiency.

Contact us now for free cleaning needs assessment and customized solutions, elevating your production environment to a higher level of cleanliness and providing strong guarantees for product quality and corporate competitiveness!

Act Now:Customize Your Rapid Clean Space!

Don’t let lengthy lead times slow down your production schedule.Contact our cleanroom experts for a free design consultation and customized quote to kickstart your fast-track production journey.